Advantage:

- DELEM SYSTEM

- FAST DELIVERY

- WITH LASER GUIDE

- DSP OPTION

- WILA OPTION

Mechanical structure

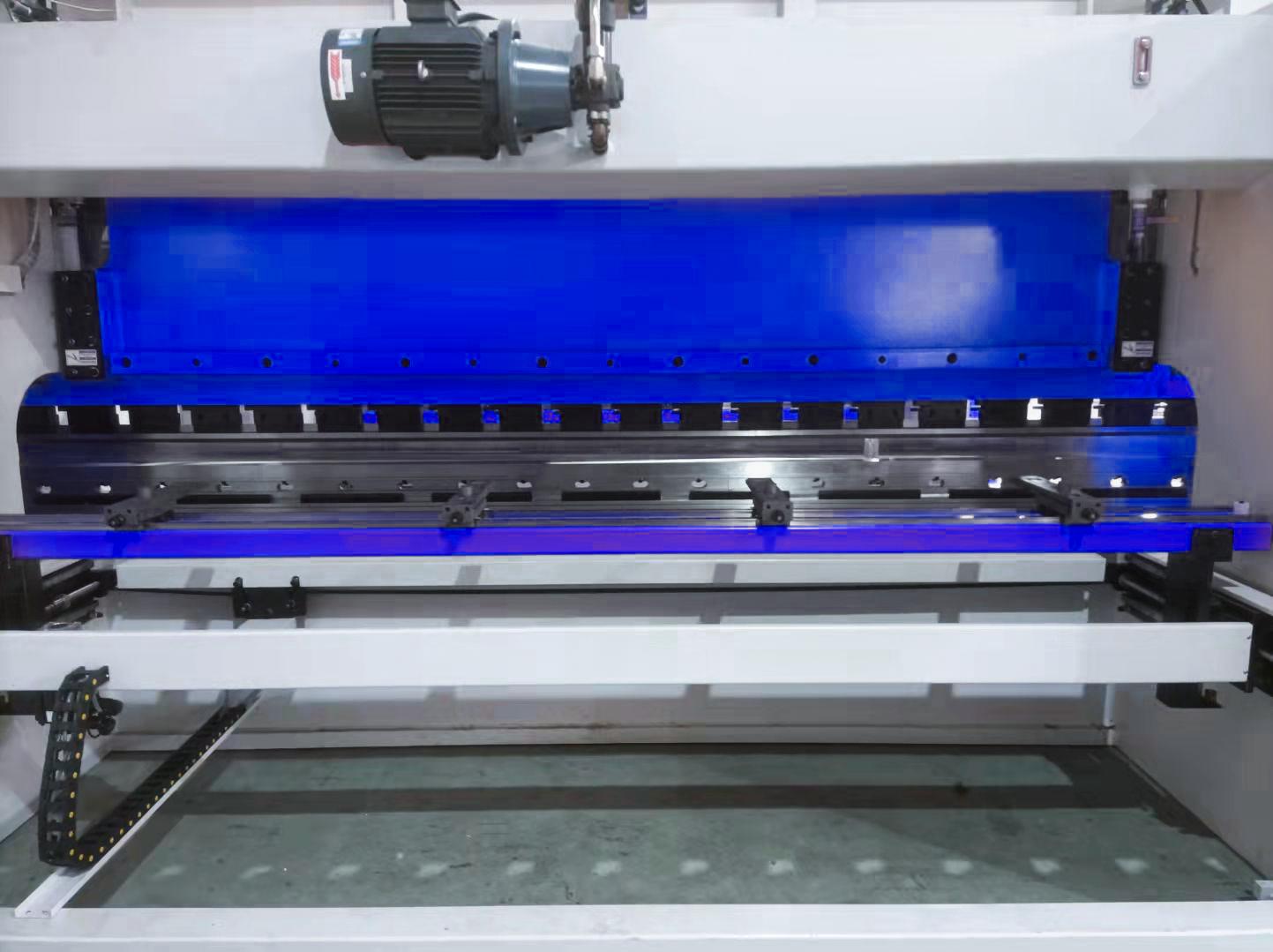

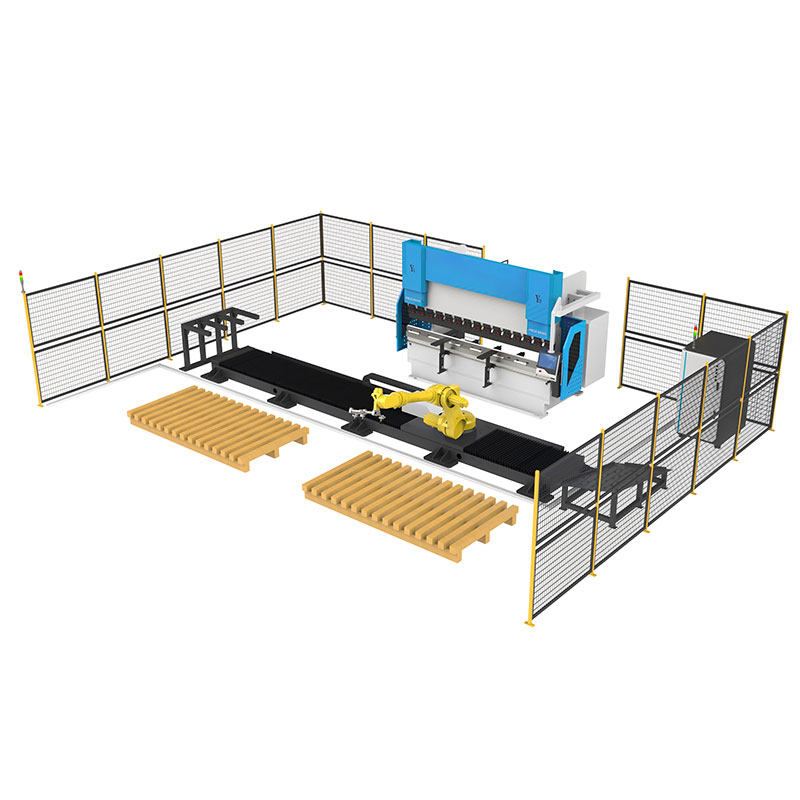

1.All technologies of this machine are from Taiwan, and its production process is the same as that in Taiwan. It is produced by HUARUI company. The main structure of this machine is automatically simulated and calculated by the latest version of mathematical trigonometric geometric function precision program of computer Pro / E3D. The tensile strength and pressure strength of the main structure and the parallel straight line of table deflection are within the safe range.

2.The machine is made of Q235B high-quality steel plate, and the joints of heavy steel plates are all broken to ensure the strength of the whole machine.

3.The whole machine is annealed and stress relieved to ensure steel strength, accuracy and structural stability.

4. After annealing, the machine is derusted by sand blasting and treated with antirust paint.

5. After the above process, the machine structure is processed and formed at one time with a large floor boring and milling machine to ensure the parallelism and verticality of each installation part.

6. The machine tool guide rail is made of high-quality materials with wear resistance, and the guide rail is equipped with lubrication device.

7. The operator can easily learn and work, and can improve the best work efficiency.

8. This machine adopts Dutch DELEM-53T oil pressure folding bed special high quality, high precision controller.

9. The x-axis of the rear retaining material is a high-precision rear retaining material group, equipped with two groups of high-precision linear sliding rails of Taiwan Shangyin. The rear retaining material is integrally formed, driven by precision ball screw drive and high-precision servo motor. The guide rail adopts linear plane sliding rail, which has the advantages of rapid and accurate positioning, no noise, stable displacement, convenient zeroing, front, rear, left and right double-stage fine-tuning function.

Hydraulic system

Hydraulic system

- The hydraulic system adopts Rexroth or the same grade, with overload protection device and can be adjusted and set to the maximum pressure.

- The hydraulic system adopts Germany Rexroth or digital closed circuit system of the same grade, which is designed and manufactured with high load and logic sealing. The closed oil pressure circuit has no noise and oil leakage.

- The working tonnage is adjusted without section, with double pressure overload safety protection valve to prevent improper action from endangering human and machine safety.

- Internal gear high-pressure oil pump can withstand high pressure and low noise.

- The seal adopts advanced modular structure, with strong sealing performance and long service life.

- The oil level height is clearly displayed, and there is a filter screen blocking warning device in the oil tank.

- The machine tool can work continuously for more than 14 hours under a certain load to ensure the continuous and stable operation of the oil pressure system and the delivery accuracy.

Accuracy of machine tool

- Repeated positioning accuracy of Y axis: ± 0.02 mm

- X-axis positioning accuracy: ± 0.1 mm

Workpiece accuracy

- Dimensional accuracy: ± 0.1 mm

- Angle: ± 0.5 °

| HPB17042 Main technical parameters of CNC bending machine |

| ► Equipment Model |

17042 |

|

| ► Control System |

DELEM-53T |

| ► Number of Control Axes |

X,Y1,Y2,R,C(4+1 Axe) |

| ► Bending Ability |

5.0*4200(CS) |

mm |

| ► Stamping Capacity |

1700 |

KN |

| ► Main motor |

11 |

KW |

| ► Table Length |

4200 |

mm |

| ► Table Width |

90 |

mm |

| ► Machine Inner Distance |

3600 |

mm |

| ► Max Opening Distance |

480 |

mm |

| ►Oil cylinder stroke |

200 |

mm |

| ► Throat Depth |

400 |

mm |

| ► Falling Speed |

180 |

mm/s |

| ► Pressure Speed |

10 |

mm/s |

| ► Recovery Speed |

120 |

mm/s |

| ► External Dimensions |

L:4400*W:1950*H:2750 |

mm |

| ► Weight |

12.3 |

T |

| ► Working Environment

Temperature |

0 ~45 ℃ |

|

| ► Power Requirements |

AC three-phase

380V/50HZ±10% |

|

Dutch DELEM-53T system function

1. “10.1”high resolution true color TFT display.

2. Automatically calculate the total length of bending workpiece material.

3. Display of workpiece shape change before and after bending.

4. Output tonnage is calculated automatically by computer.

5. The folding plate points back to the gauge axis to avoid material.

6. Rear material stop delay action function, which can be controlled externally.

7. The lifting speed of pressure seat can be adjusted without section.

8. You can use shortcut keys to quickly switch directly on the programming and processing interface, making the operation more convenient and humanized.

9. The standard configuration is 3 + 1 axis (Y1, Y2, x, and compensation axis), and another optional axis can be used for R axis or Z axis.

10. The opening distance and slow point distance of the upper die are automatically set by the computer.

11. The workpiece is counted 9999 times, and the single project is repeated 99 times. The programs can be connected with each other.

12. Mold data can be stored in 30 groups of upper mold programs and 30 groups of lower mold programs, and the compressive strength of the mold can be input to prevent mold damage due to overpressure.

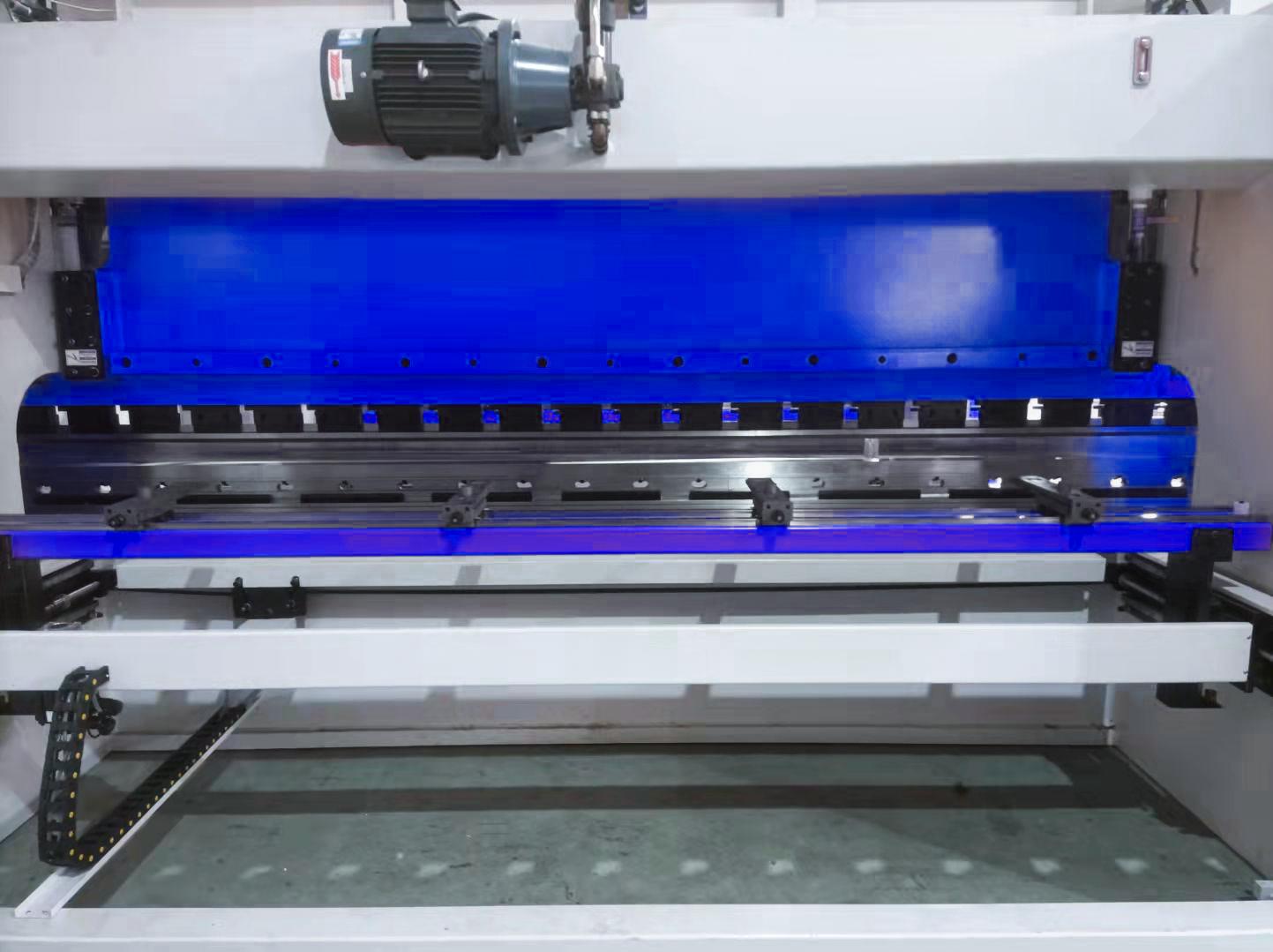

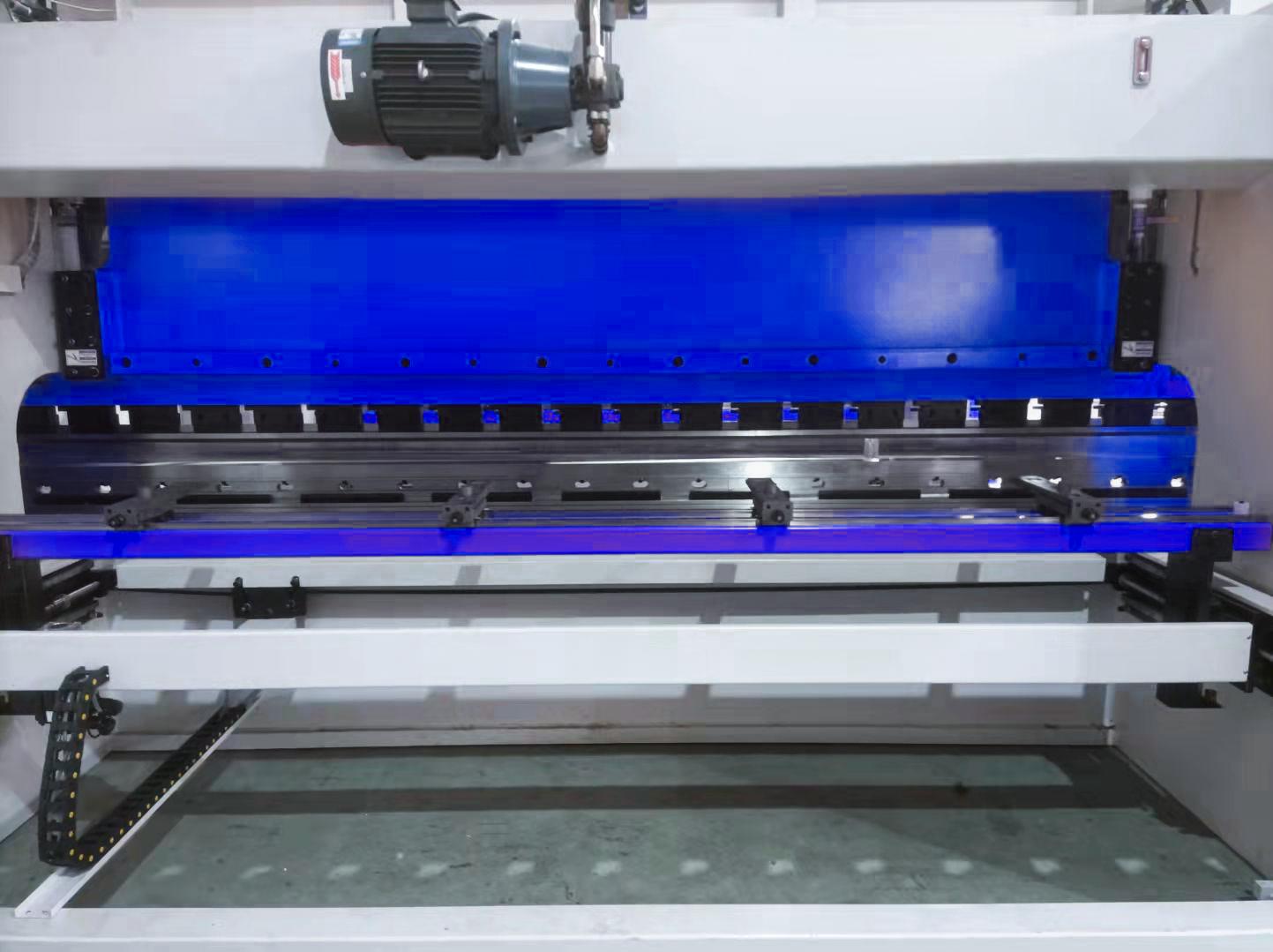

13. High precision upper and lower segmented die is printed with die length and angle on the front, which is convenient for selection.

14. Support servo or frequency conversion control. Advanced Y-axis control algorithm can control.

15. Computer convertible languages: English, simple and complex.

16. European Bosch Rexroth oil pressure system is adopted, and Y1 and Y2 can be adjusted independently.

17. The operation mode is simple, which can be divided into single action, linkage and manual.

18. Conversion from metric system to British system

19. USB peripheral interface.

20. Windows basic control operation function, which can directly switch on and off the machine.

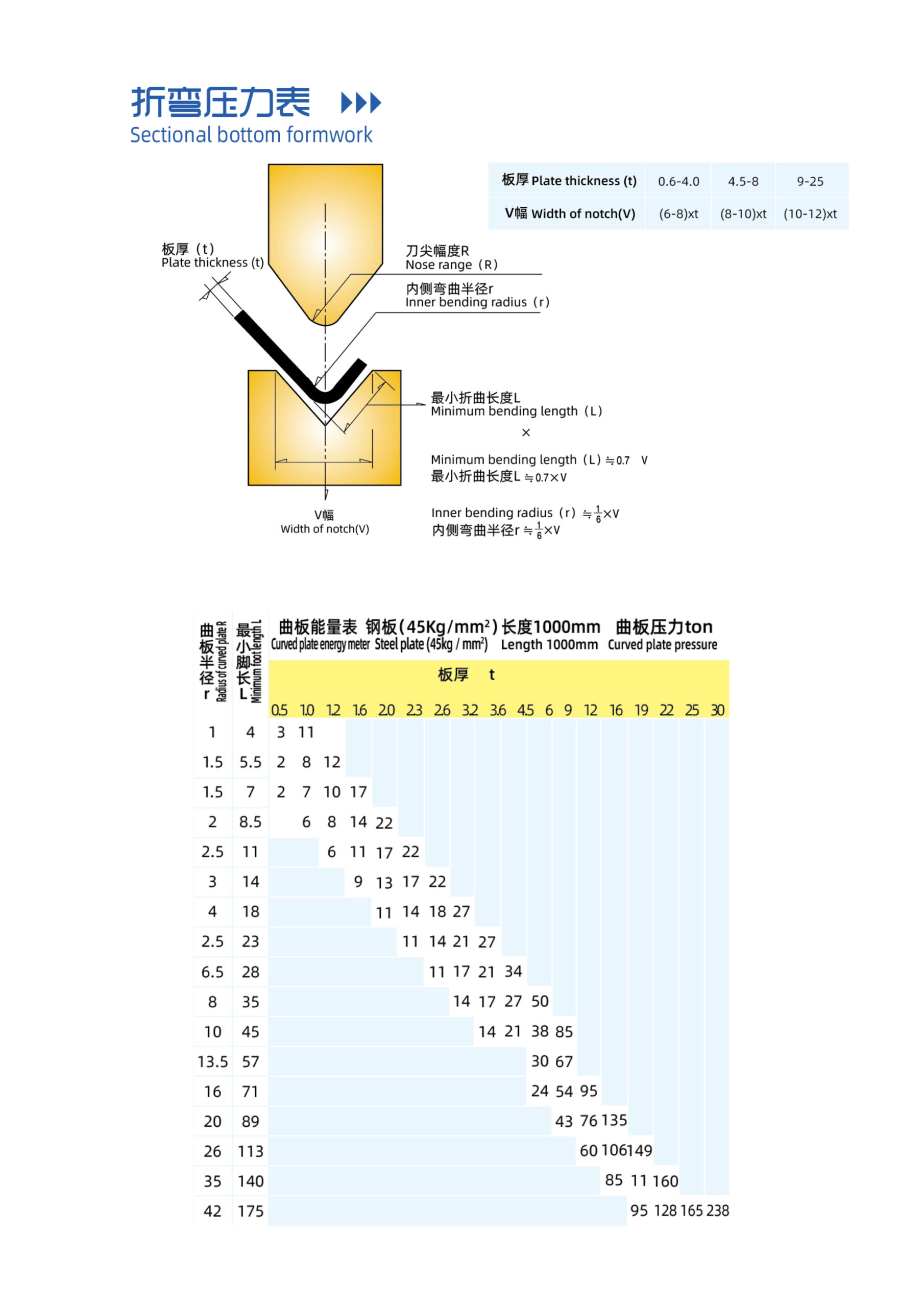

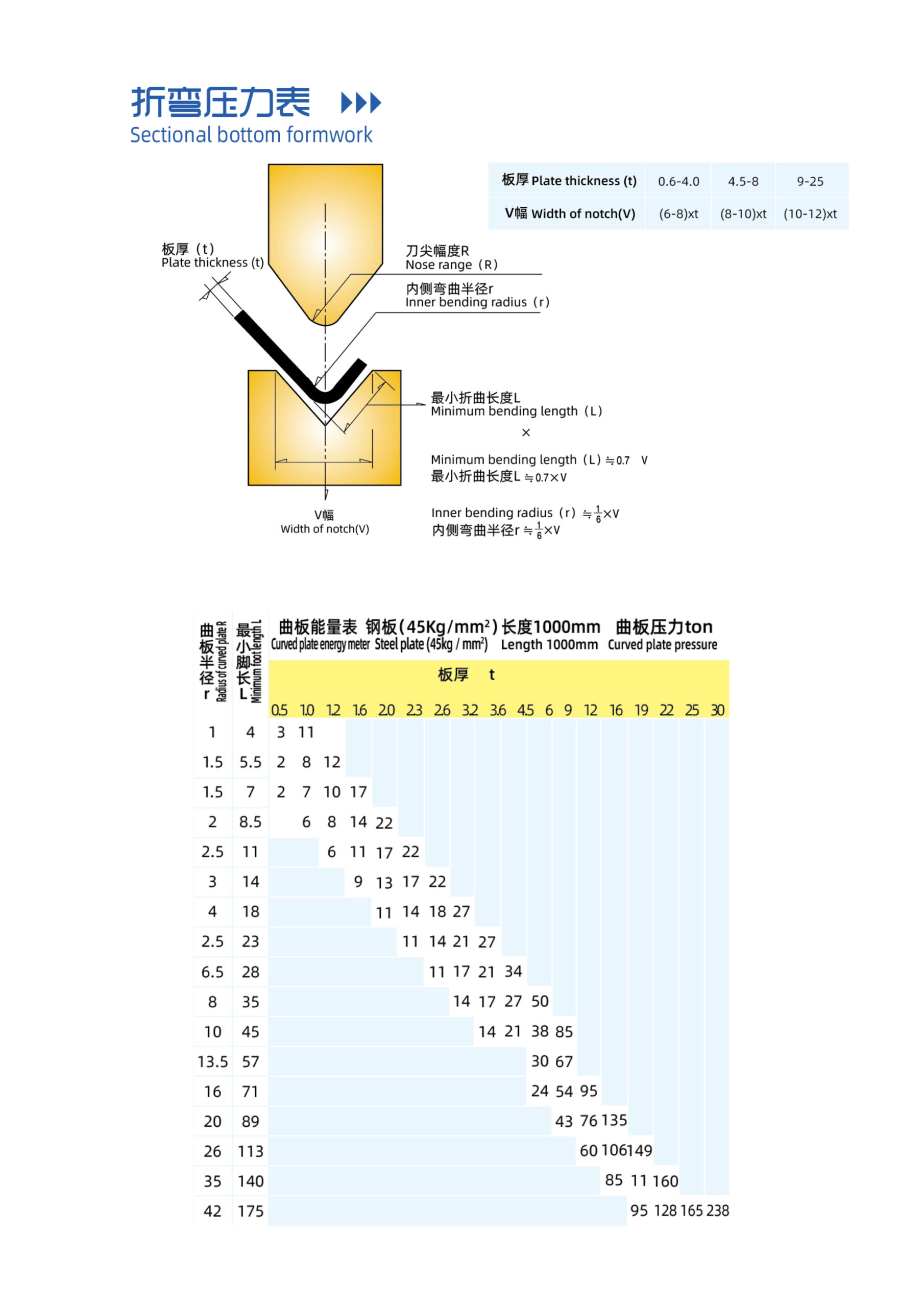

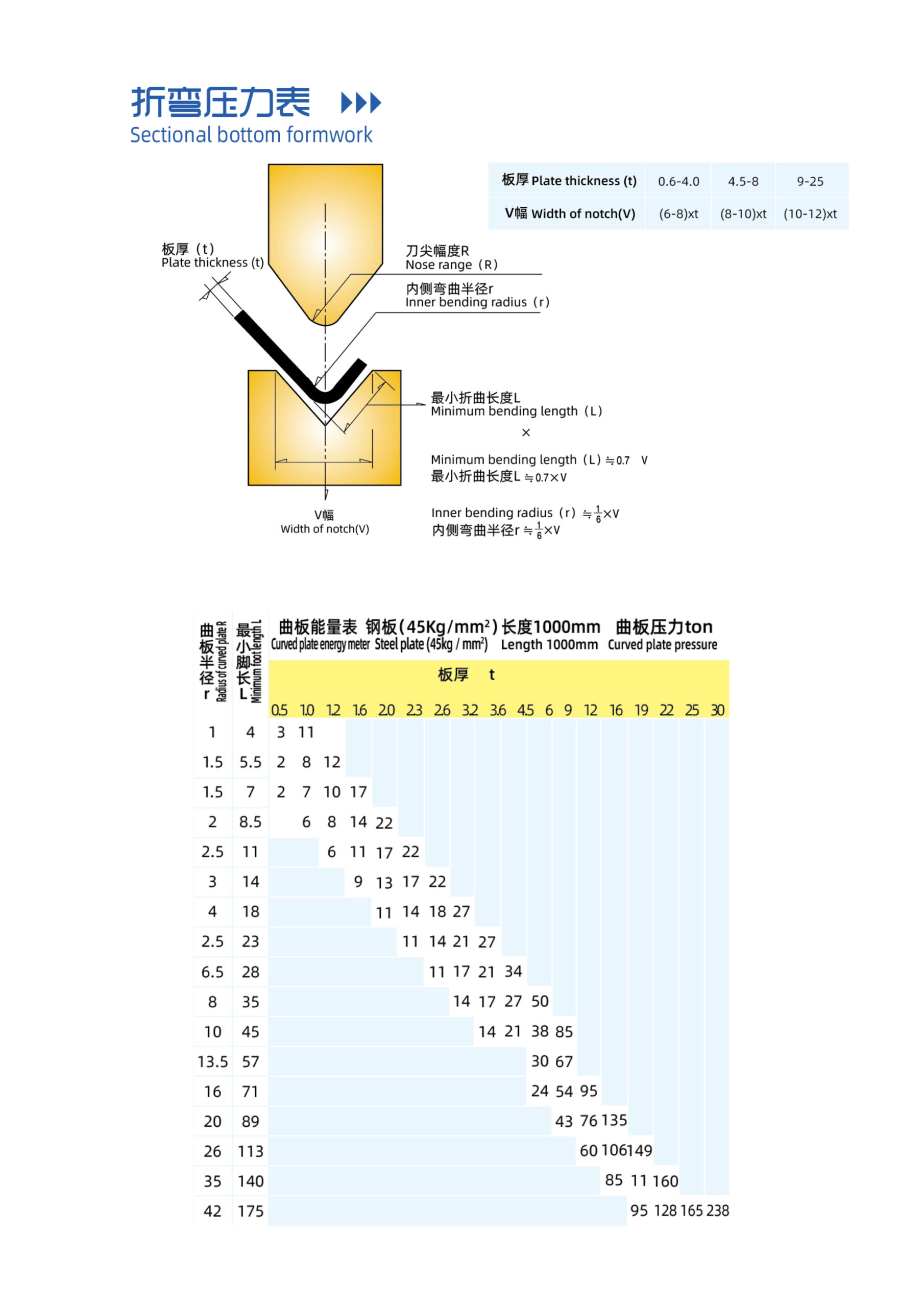

Sectional bottom formwork

List of main spare parts of machine tool

List of main spare parts of machine tool

Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) |

Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) |

Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) |

Oil Cylinder (Shanghai, HeYan)

(Turkey)

Oil Cylinder (Shanghai, HeYan)

(Turkey) |

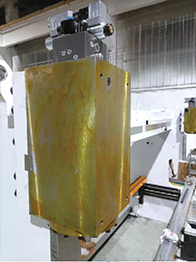

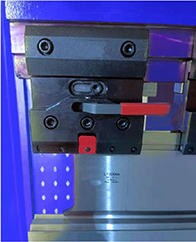

Clamping

Clamping |

GV grating ruler GV grating ruler |

Self-made support frame workbench

Self-made support frame workbench |

Mechanical compensation

Mechanical compensation |

Letter of commitment for after-sales service

For sales services, the company will be divided into pre-sale, sale, after-sales three parts, the company’s service commitment: one year warranty, lifelong service.

- Pre-sale service

The company is responsible for pre-sales to provide users with feasibility analysis and reliable equipment configuration scheme, according to the specific situation of users to provide reasonable and appropriate solutions, customer procurement consultant.

- Sale service

Help users to prepare for picking up in advance, and provide technical support and training to users in advance according to their requirements.

- After-sales service

The company is responsible for the service of users in the warranty period and beyond the warranty period, in the first after-sales service, debugging (maintenance) personnel must do the “equipment installation and commissioning Form” user confirmation signature and “equipment training form” user operator confirmation signature. In the future service, debugging (maintenance) personnel must have debugging or maintenance written report every time, all data are kept as customer files for record.

Hydraulic system

Hydraulic system

1. “10.1”high resolution true color TFT display.

2. Automatically calculate the total length of bending workpiece material.

3. Display of workpiece shape change before and after bending.

4. Output tonnage is calculated automatically by computer.

5. The folding plate points back to the gauge axis to avoid material.

6. Rear material stop delay action function, which can be controlled externally.

7. The lifting speed of pressure seat can be adjusted without section.

8. You can use shortcut keys to quickly switch directly on the programming and processing interface, making the operation more convenient and humanized.

9. The standard configuration is 3 + 1 axis (Y1, Y2, x, and compensation axis), and another optional axis can be used for R axis or Z axis.

10. The opening distance and slow point distance of the upper die are automatically set by the computer.

11. The workpiece is counted 9999 times, and the single project is repeated 99 times. The programs can be connected with each other.

12. Mold data can be stored in 30 groups of upper mold programs and 30 groups of lower mold programs, and the compressive strength of the mold can be input to prevent mold damage due to overpressure.

13. High precision upper and lower segmented die is printed with die length and angle on the front, which is convenient for selection.

14. Support servo or frequency conversion control. Advanced Y-axis control algorithm can control.

15. Computer convertible languages: English, simple and complex.

16. European Bosch Rexroth oil pressure system is adopted, and Y1 and Y2 can be adjusted independently.

17. The operation mode is simple, which can be divided into single action, linkage and manual.

18. Conversion from metric system to British system

19. USB peripheral interface.

20. Windows basic control operation function, which can directly switch on and off the machine.

Sectional bottom formwork

1. “10.1”high resolution true color TFT display.

2. Automatically calculate the total length of bending workpiece material.

3. Display of workpiece shape change before and after bending.

4. Output tonnage is calculated automatically by computer.

5. The folding plate points back to the gauge axis to avoid material.

6. Rear material stop delay action function, which can be controlled externally.

7. The lifting speed of pressure seat can be adjusted without section.

8. You can use shortcut keys to quickly switch directly on the programming and processing interface, making the operation more convenient and humanized.

9. The standard configuration is 3 + 1 axis (Y1, Y2, x, and compensation axis), and another optional axis can be used for R axis or Z axis.

10. The opening distance and slow point distance of the upper die are automatically set by the computer.

11. The workpiece is counted 9999 times, and the single project is repeated 99 times. The programs can be connected with each other.

12. Mold data can be stored in 30 groups of upper mold programs and 30 groups of lower mold programs, and the compressive strength of the mold can be input to prevent mold damage due to overpressure.

13. High precision upper and lower segmented die is printed with die length and angle on the front, which is convenient for selection.

14. Support servo or frequency conversion control. Advanced Y-axis control algorithm can control.

15. Computer convertible languages: English, simple and complex.

16. European Bosch Rexroth oil pressure system is adopted, and Y1 and Y2 can be adjusted independently.

17. The operation mode is simple, which can be divided into single action, linkage and manual.

18. Conversion from metric system to British system

19. USB peripheral interface.

20. Windows basic control operation function, which can directly switch on and off the machine.

Sectional bottom formwork

List of main spare parts of machine tool

List of main spare parts of machine tool

Hydraulic system

Hydraulic system

1. “10.1”high resolution true color TFT display.

2. Automatically calculate the total length of bending workpiece material.

3. Display of workpiece shape change before and after bending.

4. Output tonnage is calculated automatically by computer.

5. The folding plate points back to the gauge axis to avoid material.

6. Rear material stop delay action function, which can be controlled externally.

7. The lifting speed of pressure seat can be adjusted without section.

8. You can use shortcut keys to quickly switch directly on the programming and processing interface, making the operation more convenient and humanized.

9. The standard configuration is 3 + 1 axis (Y1, Y2, x, and compensation axis), and another optional axis can be used for R axis or Z axis.

10. The opening distance and slow point distance of the upper die are automatically set by the computer.

11. The workpiece is counted 9999 times, and the single project is repeated 99 times. The programs can be connected with each other.

12. Mold data can be stored in 30 groups of upper mold programs and 30 groups of lower mold programs, and the compressive strength of the mold can be input to prevent mold damage due to overpressure.

13. High precision upper and lower segmented die is printed with die length and angle on the front, which is convenient for selection.

14. Support servo or frequency conversion control. Advanced Y-axis control algorithm can control.

15. Computer convertible languages: English, simple and complex.

16. European Bosch Rexroth oil pressure system is adopted, and Y1 and Y2 can be adjusted independently.

17. The operation mode is simple, which can be divided into single action, linkage and manual.

18. Conversion from metric system to British system

19. USB peripheral interface.

20. Windows basic control operation function, which can directly switch on and off the machine.

Sectional bottom formwork

1. “10.1”high resolution true color TFT display.

2. Automatically calculate the total length of bending workpiece material.

3. Display of workpiece shape change before and after bending.

4. Output tonnage is calculated automatically by computer.

5. The folding plate points back to the gauge axis to avoid material.

6. Rear material stop delay action function, which can be controlled externally.

7. The lifting speed of pressure seat can be adjusted without section.

8. You can use shortcut keys to quickly switch directly on the programming and processing interface, making the operation more convenient and humanized.

9. The standard configuration is 3 + 1 axis (Y1, Y2, x, and compensation axis), and another optional axis can be used for R axis or Z axis.

10. The opening distance and slow point distance of the upper die are automatically set by the computer.

11. The workpiece is counted 9999 times, and the single project is repeated 99 times. The programs can be connected with each other.

12. Mold data can be stored in 30 groups of upper mold programs and 30 groups of lower mold programs, and the compressive strength of the mold can be input to prevent mold damage due to overpressure.

13. High precision upper and lower segmented die is printed with die length and angle on the front, which is convenient for selection.

14. Support servo or frequency conversion control. Advanced Y-axis control algorithm can control.

15. Computer convertible languages: English, simple and complex.

16. European Bosch Rexroth oil pressure system is adopted, and Y1 and Y2 can be adjusted independently.

17. The operation mode is simple, which can be divided into single action, linkage and manual.

18. Conversion from metric system to British system

19. USB peripheral interface.

20. Windows basic control operation function, which can directly switch on and off the machine.

Sectional bottom formwork

List of main spare parts of machine tool

List of main spare parts of machine tool

Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) Hydraulic System

(Germany, Rexrot)

Hydraulic System

(Germany, Rexrot) Oil Cylinder (Shanghai, HeYan)

(Turkey)

Oil Cylinder (Shanghai, HeYan)

(Turkey) Clamping

Clamping GV grating ruler

GV grating ruler Self-made support frame workbench

Self-made support frame workbench Mechanical compensation

Mechanical compensation