COIL FIBER LASER CUTTING MACHINE

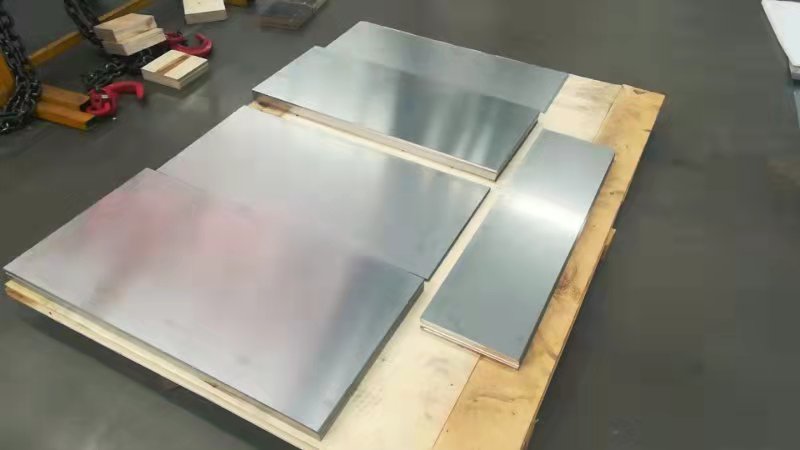

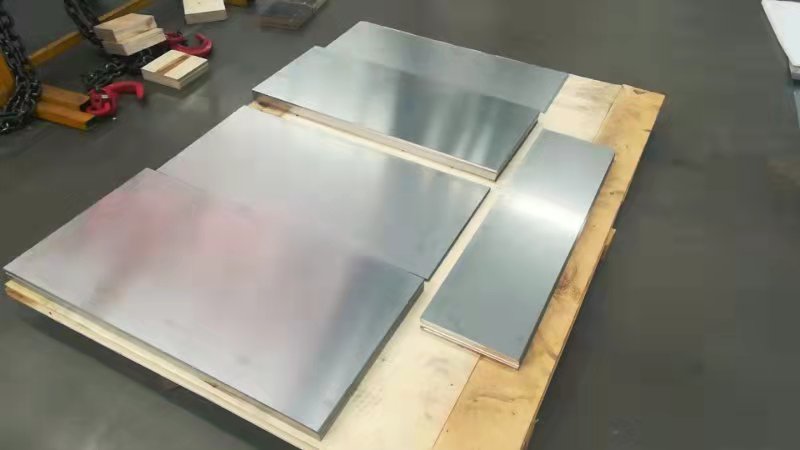

H1503 is widely used for blanking coil materials such as aluminum, stainless steel, and carbon steel.

It can uncoil carbon steel, stainless steel, and aluminum with a thickness of less than 20 mm. The most popular model is primarily designed for processing materials up to 3 mm thick, utilizing either 3000W or 6000W fiber laser power. After processing, the coil is transformed into finished products. This fiber laser cutting system for coils allows factories to reduce the number of workers needed in the workshop. It can help improve operational efficiency and save on labor costs.

The coil blanking system typically only allows for cutting large, straight pieces. However, our coil machine, equipped with a fiber laser cutting system, can cut any shape that clients want.

- Uncoiling and leveling

| Item |

1503 |

1502 |

| Coil thickness |

0.6-3mm |

0.5-2mm |

| Width of processing plate |

600-1500mm |

| Inner and outer diameter |

Φ508mm/610mm≤Φ1600mm |

| Maximum weight of coil |

10T/15T |

8T |

| Sheet flatness |

±2mm/m² |

| Maximum speed of sheet feeding |

0-10m/min |

| Plate feeding length |

0-3000mm/0-4000mm/0-6000mm |

- Main technical parameters of leveling feeder

| Items |

Parameters |

| Thickness of leveling plate |

0.6-3mm |

| Maximum width of leveling plate |

1500mm |

| Number of working rollers |

11 rollers |

| Number of supporting rollers |

2 rows up and down, and 26 in total |

| Leveling speed |

0-10m/min |

- Fiber Laser Cutting Machine Specification

| Processing format (length X width) |

3000*1500mm |

| X axis travel |

1500mm |

| Y axis travel |

3000mm |

| Z axis travel |

100mm |

| X/Y axis positioning accuracy |

±0.05mm |

| X/Y axis repeat positioning accuracy |

±0.02mm |

| PowerParameters |

Three-Phase AC380V 50Hz/60Hz |

Main Feature of our coil blanking system with fiber laser cutting machine.

1. Stepless Speed Regulation

The coil of the hydraulic coiling mandrel is driven and rotated by a deceleration motor via a sprocket chain. The plate positioned between the uncoiling and leveling processes remains in a suspended state to facilitate stress relief.

- Lightning-Cutting Glossy Blanking

The laser blanking process can be accomplished using a specialized coil laser cutter, and the laser blanking system has been developed independently. Our state-of-the-art laser technologies guarantee a superior cutting surface and customized blanking solutions. The world-renowned brand of full servo motion control systems offers rapid response times and high precision.

- Quick Stress Relief Techniques

The first patent for specialized laser leveling technology has been issued.

After the coil is uncoiled, the internal stress of the sheet is released, allowing it to become flatter as it is leveled by the leveling machine.

- Ultra-precision correction technology

A specialized lead screw nut is employed to drive the correcting roller for the installation of the sliding block. This mechanism allows the correcting tube wheel to align the plate, ensuring proper guidance and positioning. It prevents scratches on the plate during movement and accurately positions the plate without the need for laser edge detection, thereby saving time in the plate cutting process.

- Fully Automatic Assembly Line Design

From loading to uncoiling, leveling, cutting, and unloading, the fully automated assembly line design maximizes waste reduction and enhances the utilization efficiency of the sheet.

- Intelligent Systems

- The Z-axis automatic adjustment program enables follow-up control to eliminate the effects of uneven sheets.

- A user-friendly operational interface with a text display for the error analysis report.

- The type and pressure of the auxiliary gas can be selected automatically.

- Perforation Control System

- Laser Direct Pulse Power Modulation.

- A breakpoint return function.