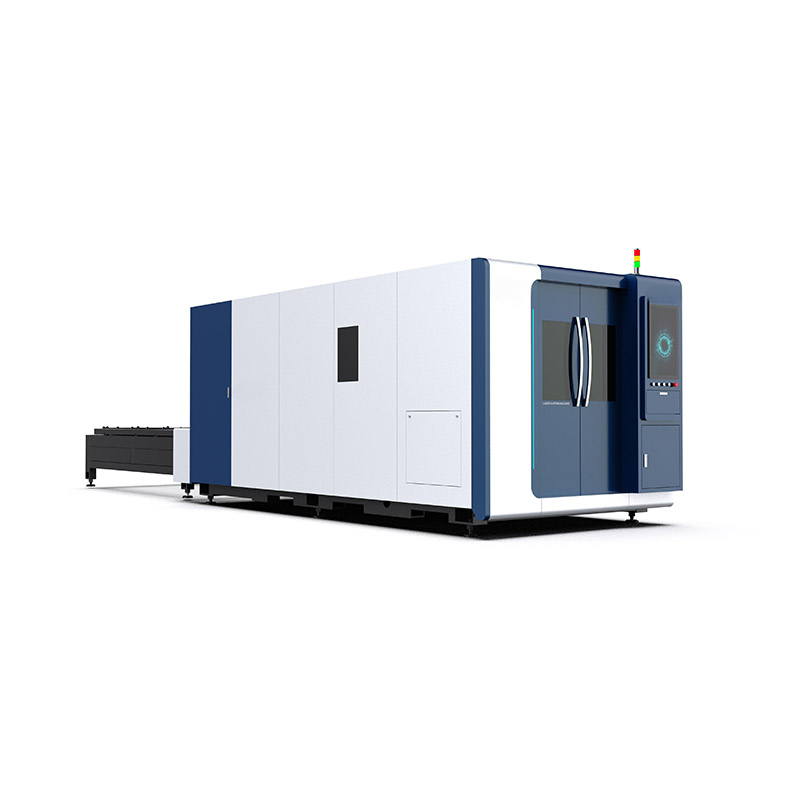

Introduction of H3015C fiber laser cutting machine

Introduction of H3015C fiber laser cutting machine

HUARUI C series fiber laser cutter is designed with protective cover and exchange table, widely equipped with 1kw to 60kw, this model can prevent the laser radiation and protect the worker safety, reduce the environment pollution; the exchange of table only takes 15 seconds.

Parameters

| Model |

H3015C |

H4020C |

H6020C |

H6025C |

| Work Area |

3000*1500mm |

4000*2000mm |

6000*2000mm |

6000*2500mm |

| Position accuracy |

±0.05mm |

| Repeated positioning |

±0.02mm |

| Max speed |

130m/min |

| Max acceleration |

1.0G |

| Total weight |

6000KG |

| Max load |

800KG |

| Power |

Three-phase AC 380V 50Hz |

Cutting range

| Material |

1000w |

1500w |

2000w |

3000w |

4000w |

6000w |

| Carbon steel(mm) |

0.4-12 |

0.4-14 |

0.4-16 |

0.4-18 |

0.4-20 |

0.4-22 |

| Stainless steel(mm) |

0.4-5 |

0.4-5 |

0.4-6 |

0.4-8 |

0.4-10 |

0.4-14 |

Main parts of our fiber laser cutter:

Application

Application Could cut: carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.

Widely used for Sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, shipbuilding etc.

FAQ:

What’s the famous machines could used for METAL CUTTTING/FABRICATION?

- Plasma cutting machine;

- Fiber laser cutting machine;

- Warerjet;

- Wire cutting;

What’s the difference between plasma cutting machine, fiber laser cutting machine, water jet, wire cutting ?

- Cutting thickness comparison:

- Laser cutting of carbon steel in industrial applications is generally below 20MM. Cutting capacity is generally below 100MM. Stainless steel industrial applications are generally below 50MM, And as the thickness of the workpiece increases, the cutting speed decreases significantly.

- Water cutting can be very thick, 0.8-100MM, or even thicker materials.

- Plasma cutting thickness is 0-120mm, and the best cutting quality range is about 20mm. The plasma system has the highest cost performance.

- Wire cutting thickness is generally 40-60mm, and the thickest can reach 600mm.

2. Cutting speed comparison:

- Using a 1200W laser to cut a 2mm thick low-carbon steel plate, the cutting speed can reach 600cm/min; cutting a 5mm thick polypropylene resin plate, the cutting speed can reach 1200cm/min. The cutting efficiency that can be achieved by EDM wire cutting is generally 20-60 square millimeters/minute, and the maximum can reach 300 square millimeters/minute; obviously, laser cutting speed is fast and can be used for mass production.

- The speed of water cutting is quite slow and is not suitable for mass production.

- The cutting speed of plasma cutting is slow and the relative accuracy is low. It is more suitable for cutting thick plates, but the end face has an inclination.

- For metal processing, wire cutting has higher accuracy, but the speed is very slow. Sometimes other methods are required to punch holes and thread wires for cutting, and the cutting size is greatly limited.

3. Cutting accuracy comparison:

- Laser cutting has a narrow incision, with the two sides of the slit parallel and perpendicular to the surface, and the dimensional accuracy of the cut parts can reach ±0.2mm. Plasma can reach within 1mm;

- Water cutting will not produce thermal deformation, with an accuracy of ±0.1mm. If a dynamic water cutting machine is used, the cutting accuracy can be improved, and the cutting accuracy can reach ±0.02mm, eliminating the cutting slope. The processing accuracy of wire cutting is generally ±0.01~±0.02mm, and the maximum can reach ±0.004mm.

4. Slit width comparison:

- Laser cutting is more precise than plasma cutting, with a small slit of about 0.5mm. The slit of plasma cutting is larger than that of laser cutting, at about 1-2mm;

- The slit of water cutting is about 10% larger than the diameter of the knife tube, generally 0.8mm-1.2mm. As the diameter of the sand knife tube expands, its incision becomes larger.

- The slit width of wire cutting is the smallest, generally around 0.1-0.2mm.

What’s the hot sale brands in the world:

Japan Amada: www.amada.co.th; their main products are Fiber laser cutting machine within 12KW; press brake; hot sale model such as EGB8025; EGB1303E; EMJ,AJ Seris;

Germany: Trump: www.trumpf.com; Their main products are Fiber laser cutting machine sheet, fiber laser tube cutting machine, press brake, auto bending center, etc. Hot sale model: TruLaser Serie 3000 Bevel Cut Edition;TruLaser Cell 5030; TruLaser Cell 5030 Hotforming Edition;TruLaser Tube 7000 fiber;

Introduction of H3015C fiber laser cutting machine

HUARUI C series fiber laser cutter is designed with protective cover and exchange table, widely equipped with 1kw to 60kw, this model can prevent the laser radiation and protect the worker safety, reduce the environment pollution; the exchange of table only takes 15 seconds.

Parameters

Introduction of H3015C fiber laser cutting machine

HUARUI C series fiber laser cutter is designed with protective cover and exchange table, widely equipped with 1kw to 60kw, this model can prevent the laser radiation and protect the worker safety, reduce the environment pollution; the exchange of table only takes 15 seconds.

Parameters

Application Could cut: carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.

Widely used for Sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, shipbuilding etc.

FAQ:

What’s the famous machines could used for METAL CUTTTING/FABRICATION?

Application Could cut: carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.

Widely used for Sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, shipbuilding etc.

FAQ:

What’s the famous machines could used for METAL CUTTTING/FABRICATION?