I.Introduction

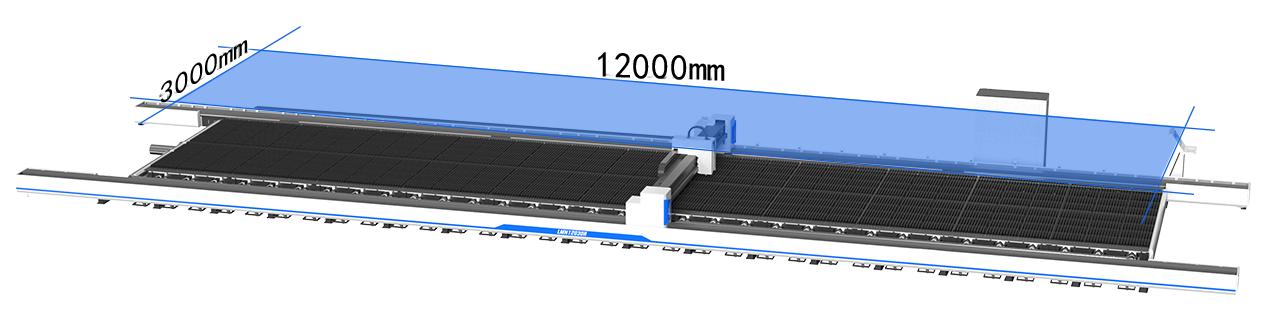

- Super-Large cutting area

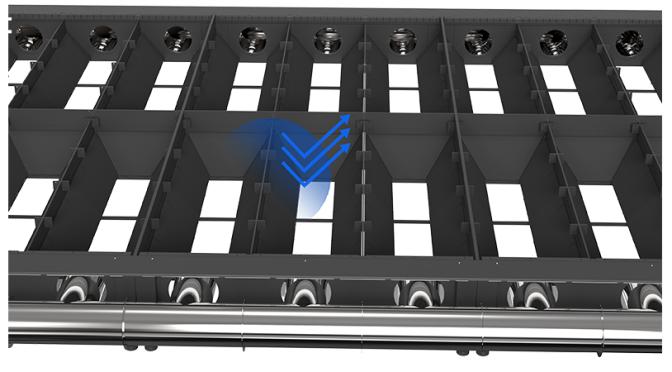

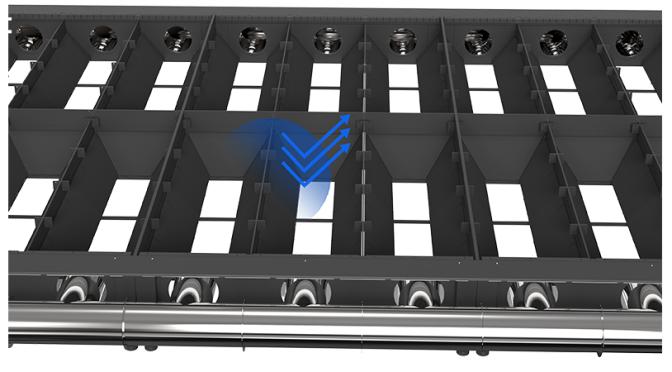

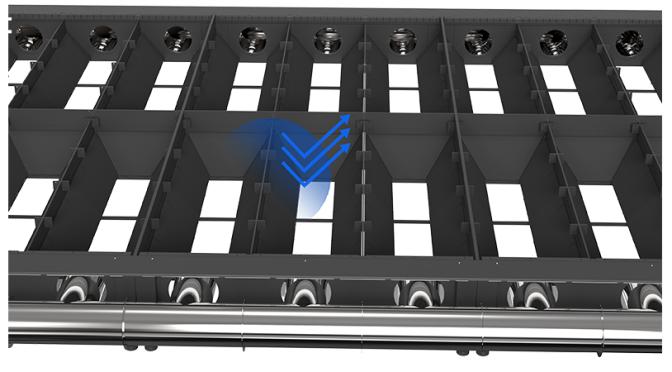

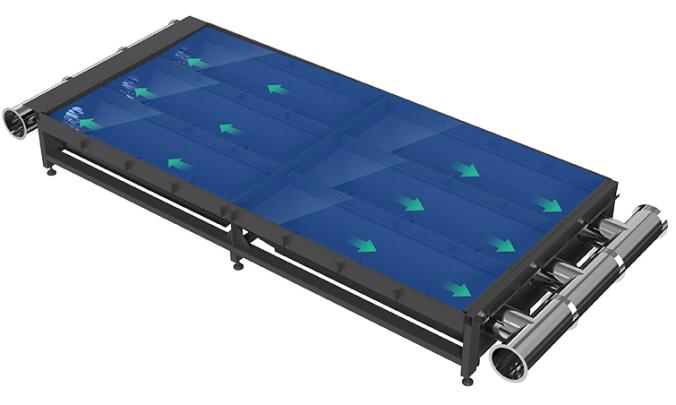

- Intelligent zonal dust removal

- Graphite anti-burn

- Automatic anti-backlash patented technology

II.Technical Parameter

| Item |

Parameters |

| 6KW |

12KW |

20KW |

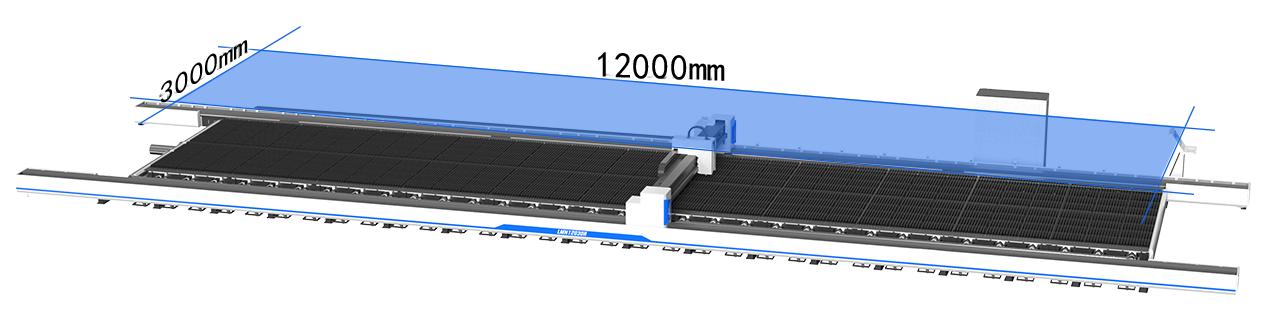

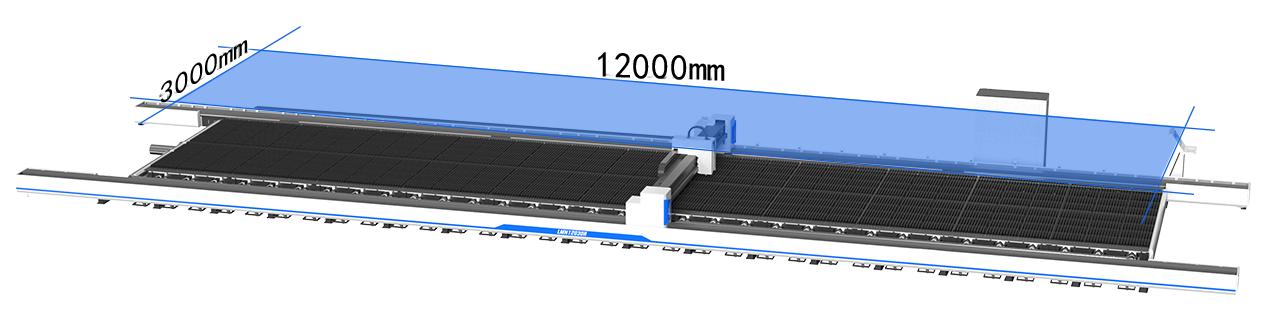

| Work Area |

12000*3000mm/39.37ft*9.84ft |

| X-axis Travel |

3000mm/9.84ft |

| Y-axis Travel |

12000mm/39.37ft |

| Z-axis Travel |

160mm/0.52ft |

| Positioning accuracy |

±0.1/10000mm |

| Repeated positioning |

±0.05mm |

| Maximum speed |

80m/min |

| Maximum acceleration |

0.8G |

| Machine Total weight(KG) |

13680KG |

14040KG |

14200KG |

| Table maximum load(KG) |

8500KG |

8500KG |

8500KG |

| Outline size(mm) |

15226*5791*1887mm |

| Power parameters |

3 phase 380V 50Hz |

| Protection Level of Total Power Supply |

IP54 |

III.Configuration

| NAME |

NO. |

BRAND |

| FIBER LASER DEVICE |

| Laser source |

1 set |

RAYCUS/MAX |

| LASER HEAD |

| Laser head |

1 set |

BOCI |

| Main Machine |

| Transmission |

4 set |

LAPPING |

| Machine bed accessories |

1 set |

Own Made |

| Motor reducer |

3 set |

MOTOREDUCER |

| Electrical and pneumatic |

1 set |

SCHNEIDER

SMC/AIRTAC |

| Server motor and driver |

4 set |

YASKAWA-S |

| Water cooling |

1 set |

HANLI |

| CNC CONTROL SYSTEM |

| FSCUT system |

1 set |

FSCUT2000S/FSCUT 8000 |

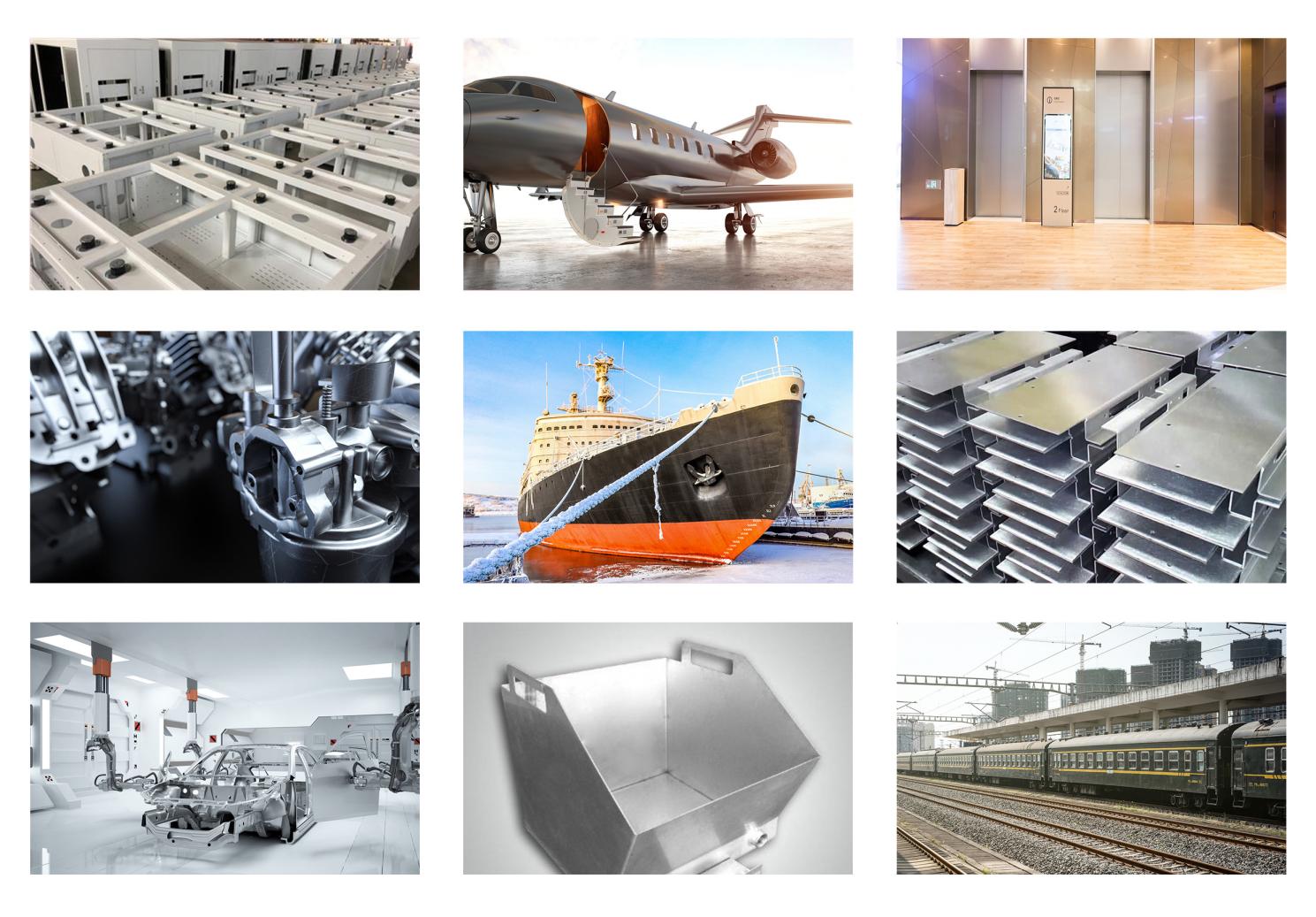

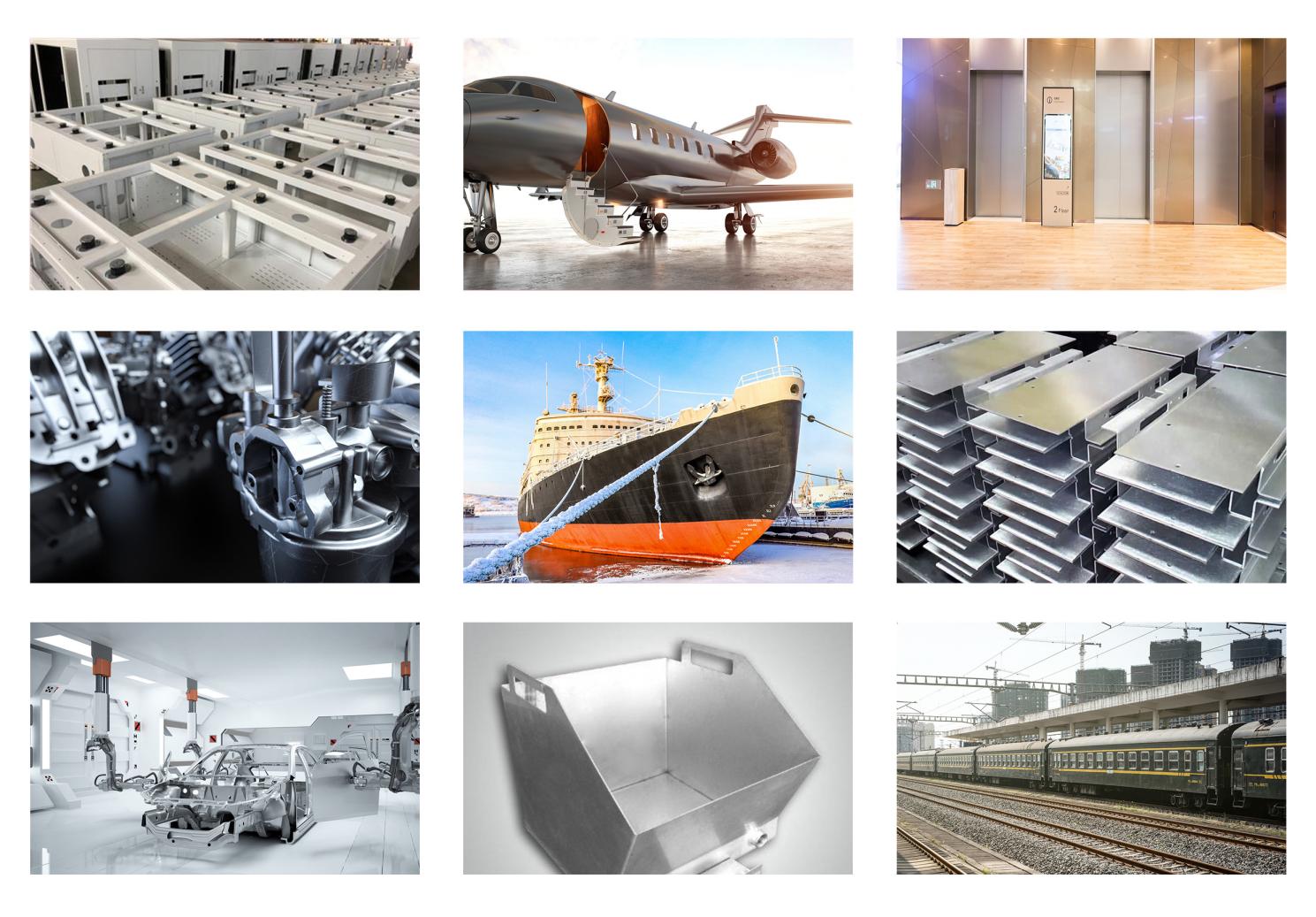

IV.Cutting Capability and Application

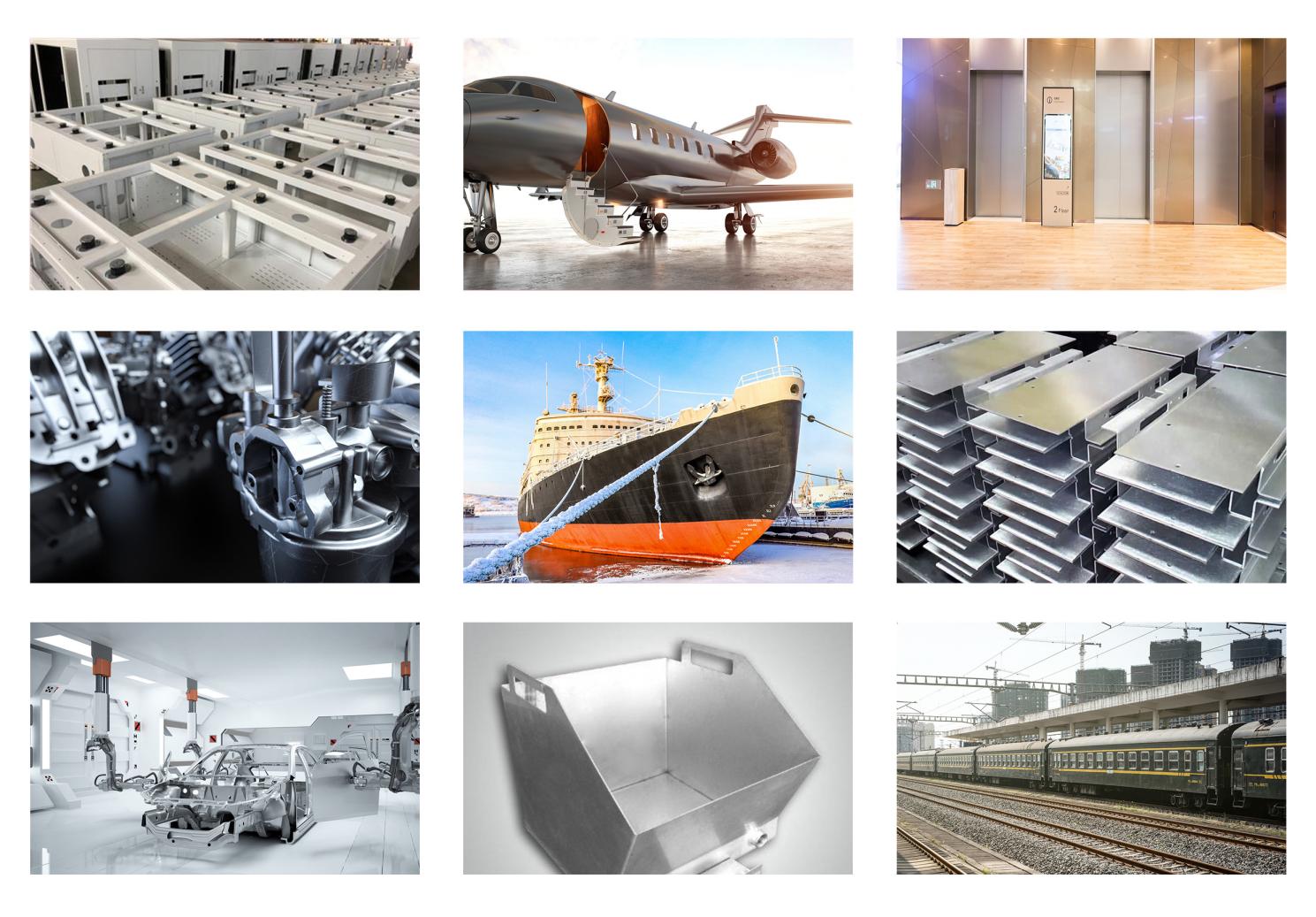

Carbon steel, stainless steel, aluminum alloy, brass, galvanized sheet, etc.

Widely used for fabrication industry, machinery industry, processing industry, our fiber laser cutting machines can make metal parts such as auto parts, electrical, elevator , petroleum machinery, food machinery, shipbuilding etc.

Cutting Thickness

Cutting Thickness

| Material |

6KW |

12KW |

20KW |

| Carbon steel(mm) |

0.5—25mm |

0.5—40mm |

0.5—50mm |

| Stainless steel(mm) |

0.5—18mm |

0.5—30mm |

0.5—50mm |

| Brass (mm) |

0.5—12mm |

0.5—20mm |

0.5—30mm |

| Aluminum (mm) |

0.5—12mm |

0.5—20mm |

0.5—50mm |

Cutting Parameters

| Material |

Thickness(MM) |

6KW |

12KW |

20KW |

| Cutting Speed(m/min)(gas) |

Cutting Speed

(m/min)(gas) |

Cutting Speed

(m/min)(gas) |

| Stainless Steel |

6 |

6.0-7.0 (N2) |

17-20 (N2/Air) |

23-25 (N2) |

| 10 |

1.8-2.5 (N2) |

7.0-9.0 (N2/Air) |

15-17 (N2) |

| 14 |

0.8-1.2 (N2) |

3.0-3.5 (N2/Air) |

10-12 (N2) |

| 20 |

|

1.4-1.8 (N2/Air) |

2.5-2.8 (N2) |

| 30 |

|

0.6-0.8 (N2/Air) |

1.5-1.8 (N2) |

| 40 |

|

0.25-0.5 (N2/Air) |

0.5-0.8 (N2) |

| 50 |

|

0.1-0.3 (N2/Air) |

0.18 (N2) |

| Carbon Steel |

10 |

2.0-2.3 (O2) |

2.3-3.0/8.0-9.0 (O2/Air) |

10-12(AIR) |

| 16 |

0.7-1.4 (O2) |

1.5-3.0 (O2) |

4.5-5.5(AIR) |

| 20 |

0.6-1.2 (O2) |

1.2-1.5 (O2) |

2.5-3(AIR) |

| 25 |

0.5-0.7 (O2) |

0.8-1.1 (O2) |

1.3-1.5(O2) |

| 30 |

|

0.4-1.0 (O2) |

1.1-1.3(O2) |

| 40 |

|

0.2-0.4 (O2) |

0.2-0.85(O2) |

| 50 |

|

0.18 (O2) |

0.2-0.5(O2) |

| Brass |

5 |

5.0-6.0(N2) |

13-16(N2) |

25-28(N2) |

| 8 |

1.5-2.0(N2) |

6.0-8.0(N2) |

17-20(N2) |

| 10 |

1.0-1.5(N2) |

4.5-5.5(N2) |

10-13(N2) |

| 16 |

|

1.2-1.6(N2) |

2.5-3.5(N2) |

| 20 |

|

0.6-0.8(N2) |

1.8-2.3(N2) |

| 30 |

|

|

1.2-1.5(N2) |

| Aluminum |

8 |

2.0-3.0(N2/Air) |

6-10(N2/Air) |

18-20(N2) |

| 10 |

1.0-1.7(N2/Air) |

5-7(N2/Air) |

14-16(N2) |

| 16 |

|

1.5-1.8(N2/Air) |

5-8(N2) |

| 20 |

|

1.0-1.5(N2/Air) |

2.5-4.5(N2) |

| 30 |

|

0.4-0.6(N2/Air) |

1.8-2.3(N2) |

| 40 |

|

0.3-0.5(N2/Air) |

0.8-1(N2) |

| 50 |

|

0.1-0.3(N2/Air) |

0.3-0.5(N2/Air) |

V.Main Features

High strength machine bed; graphite anti-burn

The motion system is completely separated from the work surface, cutting at will, without deformation of the bed. In addition, it is equipped with graphite anti-burning technology, which can withstand high temperature of 3000℃.

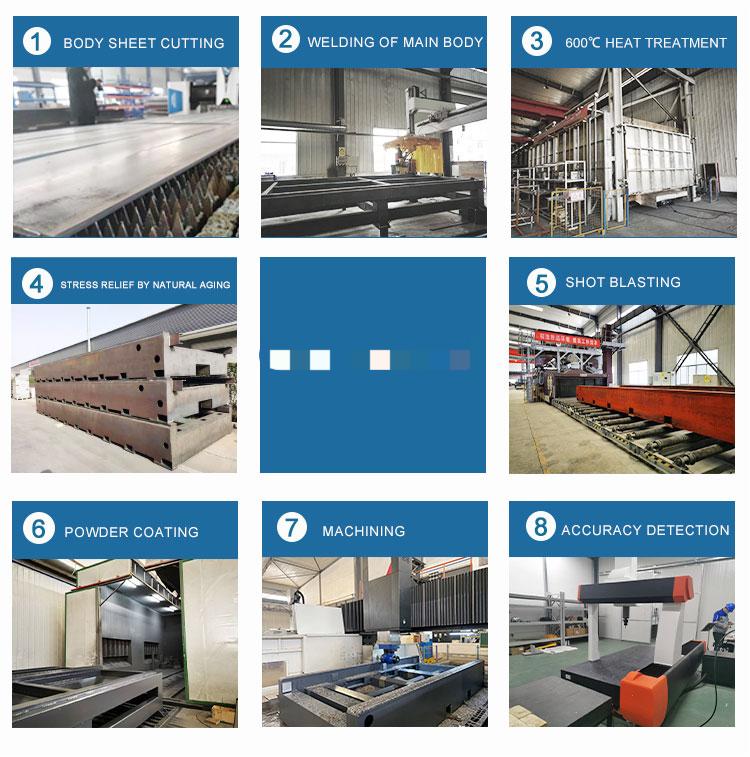

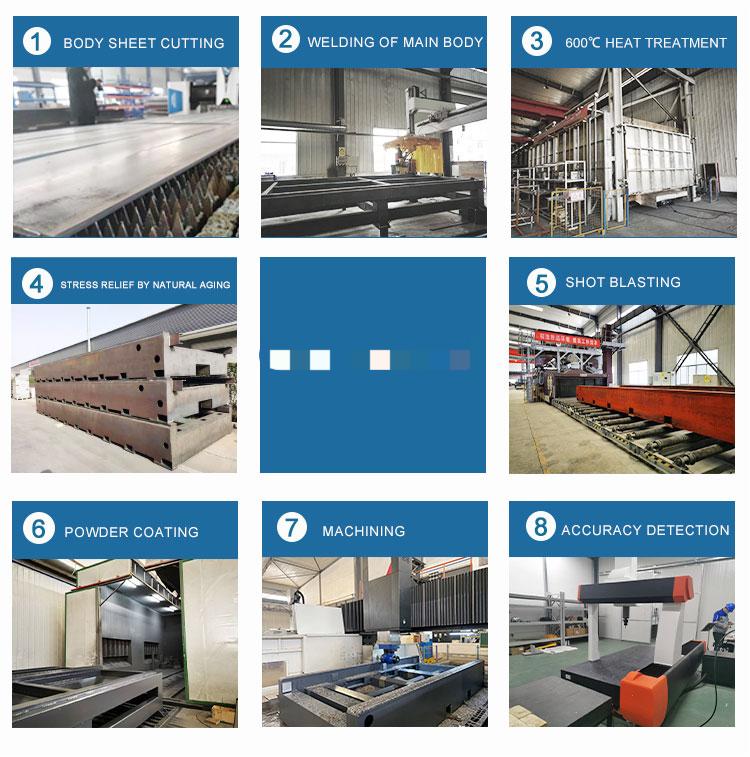

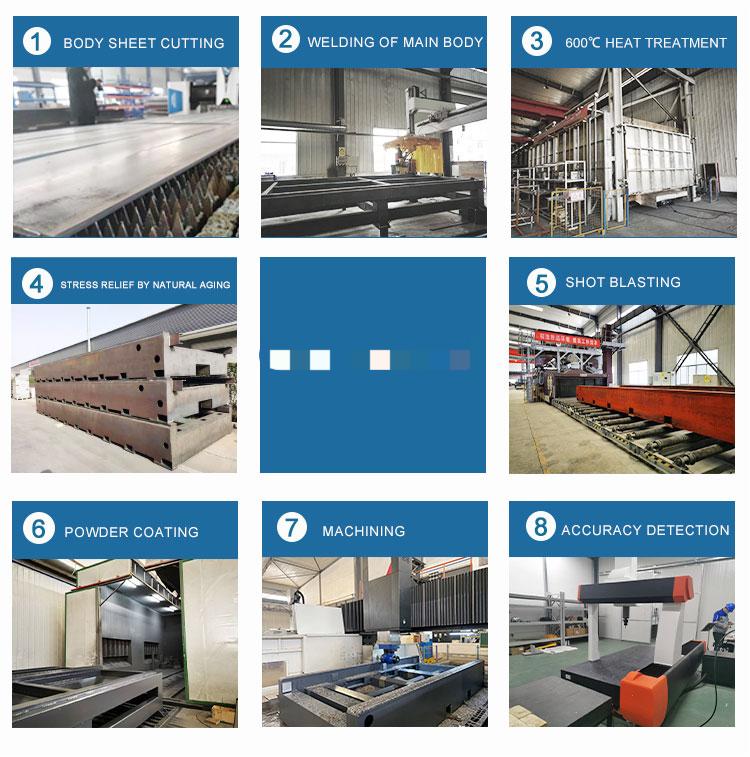

- Machine Bedprocessing process

Senfeng leiming has an independent bed production workshop. Many important process such as bed welding, heat treatment, shot blasting, cleaning, painting are all carried out in the workshop. Strictly control the quality of the bed, and timely delivery.

- Intelligent zonal dust removal

Use the function of zonal dust removal. For example, dividing a 20m*4m cutting area into small areas (2m*0.5m), and installing evacuation devices on the side to make the smoke exhaust smoother.

u Supper large cutting area

Laser power from 6KW to 60KW, which can cut medium and thick plates over 20mm in batches for a long time, and cut ultra-thick plates over 50mm in the limit;

Optional ultra-large format, processing width up to 3000mm, length can be customized according to user processing requirements;

Wide range of processing materials, large size steel can be processed.

The gas circuit system adopts the control valves and proportional regulating valves of well-known brands SMC and AIRTAC, and the pressure and flow of each gas are controlled electrically.

Cutting assist gas (O2, N2, compressed air, etc.).

- Patented technology of automatic anti-backlash device

For a large-stroke laser cutting machine, the running parallelism and straightness of the rack must be guaranteed, and the repeat positioning accuracy of the entire machine must be controlled within 0.05mm.

The elastic engagement of the rack and pinion must be carried out to ensure a degree of relaxation.

- Automatic gas distribution device for auxiliary gas

The 12030R laser cutting machine is equipped with three different gases, namely air, nitrogen (300psi) and oxygen, each of which can be individually controlled for its flow and pressure. The equipment software terminal is configured to automatically select the auxiliary gas function. The type and pressure of the auxiliary gas can be automatically set and selected through the numerical control program, without manual operation. The pressure of compressed air and oxygen can be adjusted between 150 mBar and 6 Bar, and the pressure of nitrogen can be adjusted between 150 mBar and 25 Bar. In addition, the actual air pressure at the exit of the cutting head can also be easily read and displayed on the panel in real time.

VI.More Details

|

Professional optical fiber cutting head (BOCI) (Optional)

1) Cost-effective cutting head

2) 12 sets of smart sensors provide guarantee for long-term stable work

3) Accurately locate module faults

4) Modular design, solve the problem quickly, low maintenance cost |

|

20KW Raycus Laser Source (Optional)

1) The electro-optical conversion efficiency reaches 37% or more

2) The cutting speed of thin and thick plates is greatly improved

3) 100nm fiber core output stronger penetrating power

4) Intelligent control system

5) Safety protection reaches the European standard level |

|

Storm Cutting System-FSCUT8000 (Optional)

Stable and reliable, easy to deploy and debug, safe in production, rich in functions, and excellent in performance; support and provide modular, personalized, automated, and information solutions. It is the highest-end bus-type dedicated laser cutting system currently on the market. It can realize the memory cache, has a powerful cutting process database, all kinds of cutting parameters of different thicknesses and plates, fast operation and efficient cutting. |

|

Water Cooling System

Large cooling capacity, stable performance, trouble-free, clean water quality, good heat exchange effect with fiber laser, and linkage signal to protect the laser |

VII.Cost

| Mode |

6KW |

12KW |

20KW |

| AIR |

O2 |

N2 |

AIR |

O2 |

N2 |

AIR |

O2 |

N2 |

| Electricity consumption |

laser source |

20KW |

20KW |

20KW |

42KW |

42KW |

42KW |

67KW |

67KW |

67KW |

| Chiller |

10.33KW |

10.33KW |

10.33KW |

14.5KW |

14.5KW |

14.5KW |

17.5KW |

17.5KW |

17.5KW |

| Air compressor |

15KW |

/ |

/ |

22KW |

/ |

/ |

22KW |

/ |

/ |

| Machine body |

8KW |

8KW |

8KW |

8KW |

8KW |

8KW |

15KW |

15KW |

15KW |

| Dust removal equipment |

11KW |

11KW |

11KW |

11KW |

11KW |

11KW |

11KW |

11KW |

11KW |

| Gas Consumption&Consumable parts

(1USD ≈ 6.44RMB)

|

RMB/H |

0.5/H |

4.5/H |

60.5/H |

0.5/H |

4.5/H |

60.5/H |

0.5/H |

4.5/H |

60.5/H |

| USD/H |

0.08 |

0.7 |

9.4 |

0.08 |

0.7 |

9.4 |

0.08 |

0.7 |

9.4 |

| Total Power (KW) |

64.33KW |

49.33KW |

49.33KW |

97.5KW |

75.5KW |

75.5KW |

132.5KW |

110.5KW |

110.5KW |

| Total Power Consumption (KW/H) |

38.6KW/H |

29.6KW/H |

29.6KW/H |

58.5KW/H |

45.3KW/H |

45.3KW/H |

79.5KW/H |

66.3KW/H |

66.3KW/H |

| Total Operation Cost

(1RMB/KW/H) |

39.1 |

34.1 |

90.1 |

59 |

49.8 |

105.8 |

80 |

70.8 |

126.8 |

| 6.07 |

5.3 |

14 |

9.17 |

7.74 |

16.44 |

12.43 |

11 |

19.7 |

| Mode |

6KW |

12KW |

20KW |

VIII.Product Certification

Huarui fiber laser machines got the certificates: CE,FDA,ETL.

IX.5 Star Service

IX.5 Star Service

1.24 hours a day (mainly for international), 7 days a week, 365 days a year at any time to receive repair calls;

2.Within 10 minutes, technical engineers will consult, fix maintenance plan in one hour, and engineers sending plan in one working day.

1.The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

2.The seller will provide technical guide’s e-mail, telephone, WeChat, WhatsApp and so on.

3.The seller should pay for the travel expense if local service needed within warranty time.

1.The warranty of laser source is 2 years.

2.The warranty of the machine is 2 years(main spare parts),except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

3.Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4.Exceeding the warranty period, parts need to be repaired or changed, shall be paid.

1.Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for quick repair of difficult faults, and warning of matters needing attention in use;

2.Regular service: regular maintenance reminder, regular door-to-door service, regular promotional activities;

3.Value-added services: equipment software and hardware upgrading services

Our branches in United States,Germany, India,Pakistan,Serbia provide localized services and technical support for global customers.

X.Customer Testimonials

XI.Company Strength

XI.Company Strength

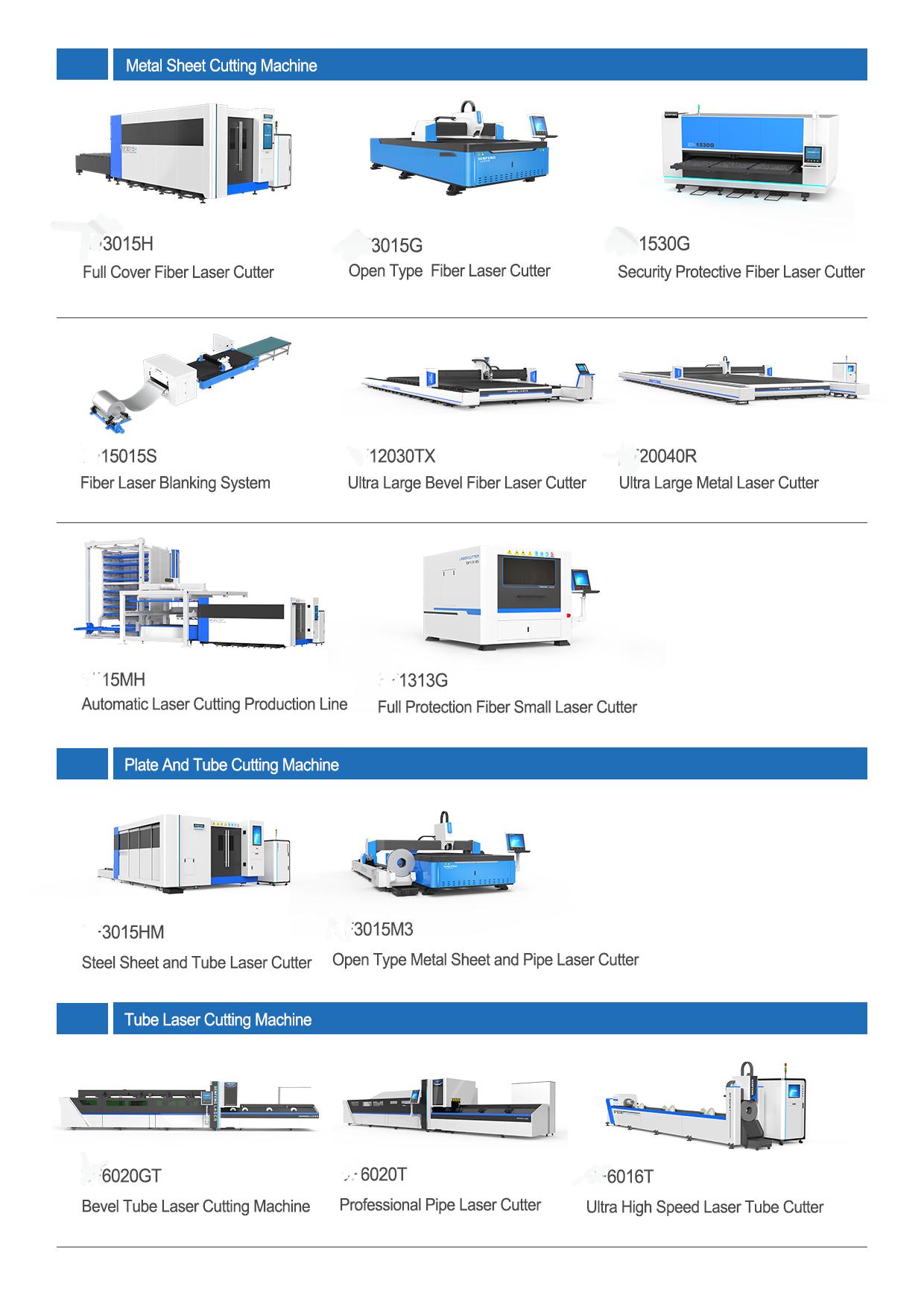

is a leading manufacturer engaged in the research, development, production, sale and service of fiber laser cutters, fiber laser cleaning machine, laser marking machine,laser welding machine ,3D robot,press brake bending machine,metal sander,etc. Products sold in more than 180 countries and regions.

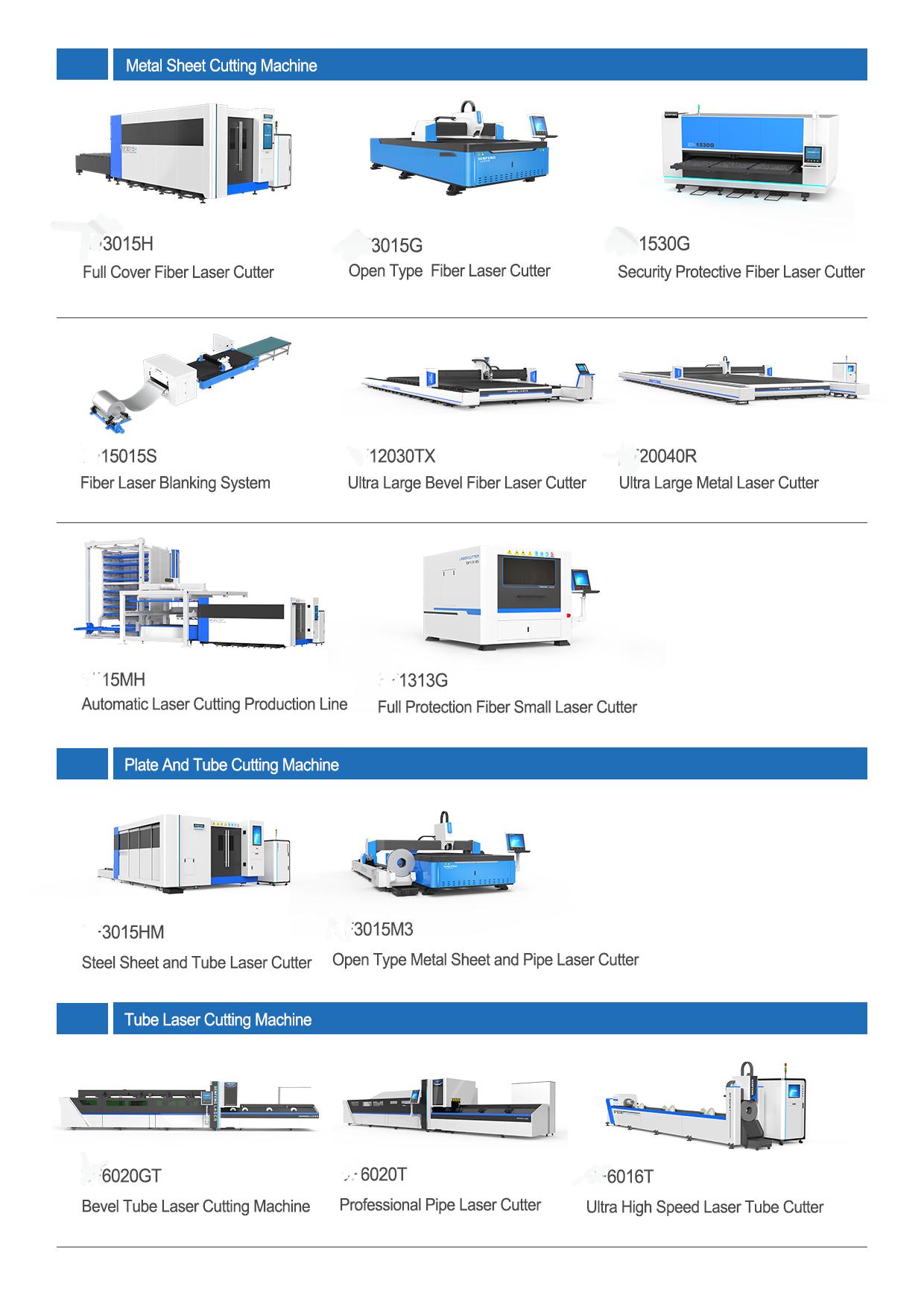

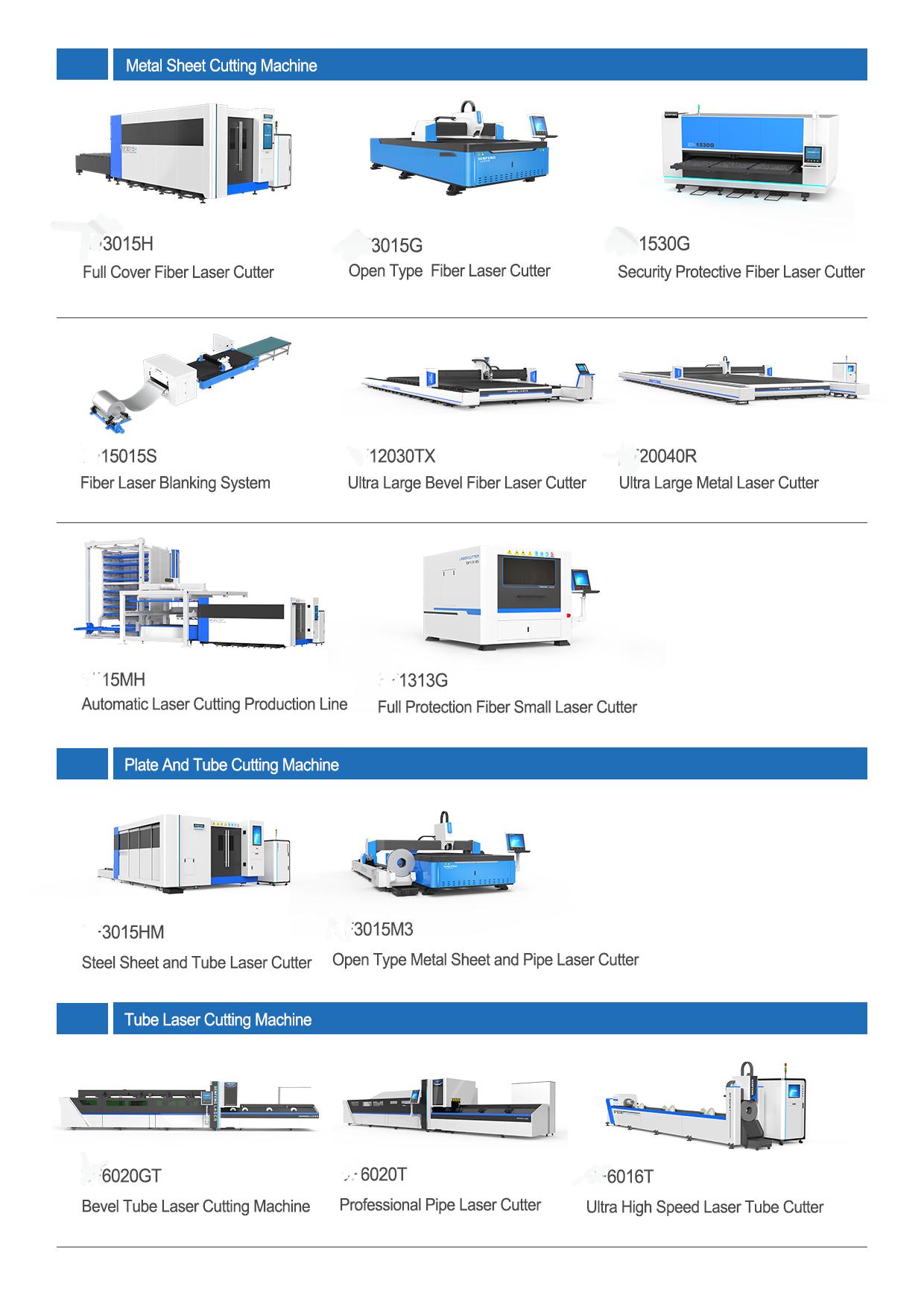

Product Line

Product Line

Cutting Thickness

Cutting Thickness

The motion system is completely separated from the work surface, cutting at will, without deformation of the bed. In addition, it is equipped with graphite anti-burning technology, which can withstand high temperature of 3000℃.

The motion system is completely separated from the work surface, cutting at will, without deformation of the bed. In addition, it is equipped with graphite anti-burning technology, which can withstand high temperature of 3000℃.

IX.5 Star Service

IX.5 Star Service

XI.Company Strength

XI.Company Strength

Product Line

Product Line

Cutting Thickness

Cutting Thickness

The motion system is completely separated from the work surface, cutting at will, without deformation of the bed. In addition, it is equipped with graphite anti-burning technology, which can withstand high temperature of 3000℃.

The motion system is completely separated from the work surface, cutting at will, without deformation of the bed. In addition, it is equipped with graphite anti-burning technology, which can withstand high temperature of 3000℃.

IX.5 Star Service

IX.5 Star Service

XI.Company Strength

XI.Company Strength

Product Line

Product Line