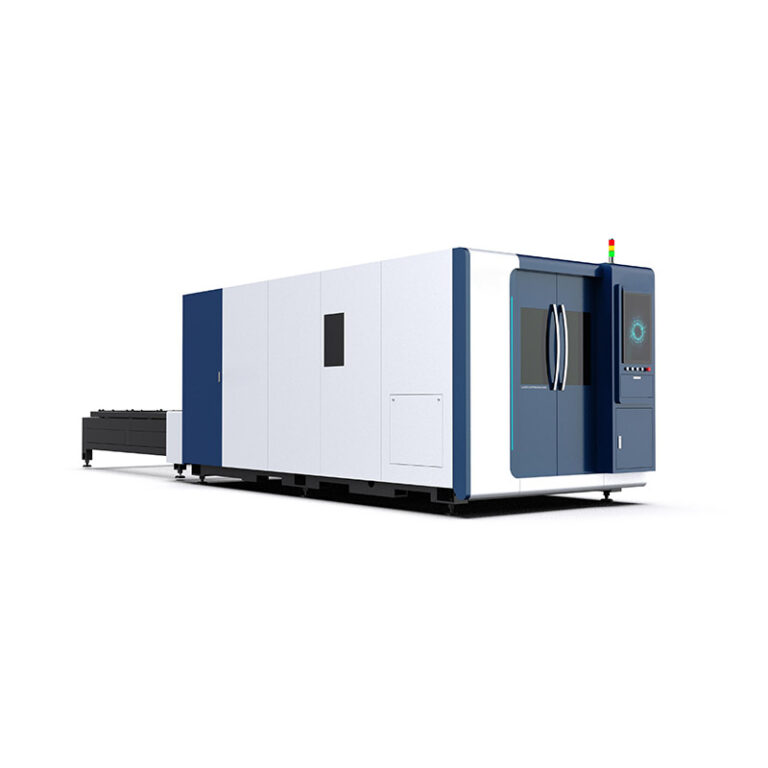

H3015C METAL FIBER LASER CUTTING MACHINE Application Fields

The H3015C metal fiber laser cutting machine has a wide range of applications, covering multiple industrial manufacturing industries, as follows: 1、 Metal sheet processing industrySheet metal processing: H3015C can efficiently cut various metal sheets such as carbon steel plate, stainless steel plate, aluminum alloy plate, galvanized plate, color steel plate, etc., meeting the high-precision processing…