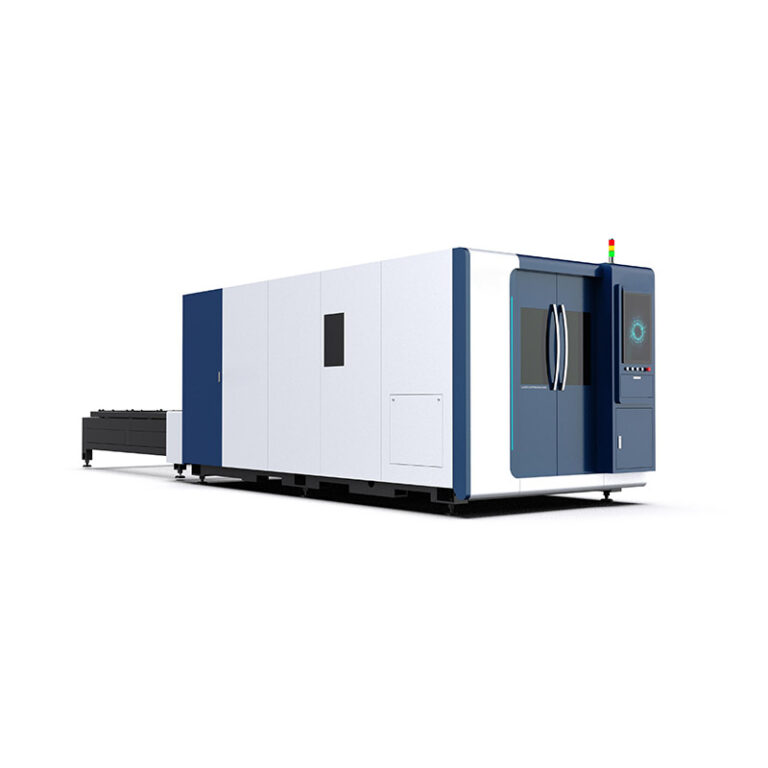

Technical characteristics of fiber laser marking machine

Fiber laser marking machine occupies an important position in the industrial processing field with its excellent technical characteristics, and its core advantages are reflected in the following aspects:

1、 Efficient and energy-saving: leading industry in electro-optical conversion rate

The fiber laser marking machine uses a fiber laser as the light source, with an electro-optical conversion efficiency of over 28%, far exceeding traditional laser marking machines (2% -10%). This feature significantly reduces energy consumption during long-term operation, for example, the overall power consumption of the device is usually less than 1000 watts, which is only 1/25 of traditional devices. Meanwhile, its water free design (only requiring air cooling) further reduces energy consumption, in line with the trend of green manufacturing.

2、 Ultra long lifespan and maintenance free: reducing overall costs

The lifespan of fiber lasers can reach over 100000 hours. Calculated based on 24 hours per day and 365 days per year, the theoretical lifespan exceeds 10 years. Its sealing structure and air cooling method avoid the risk of shutdown caused by water cooling system failure in traditional lasers, truly achieving “instant use”. This stability is particularly suitable for automated production lines, reducing production interruptions caused by equipment maintenance.

3、 High precision machining: micrometer level marking capability

The output beam quality of the fiber laser marking machine is excellent (close to the ideal beam), and the focused spot diameter can be less than 0.01 millimeters, supporting fine processing at the micrometer level. For example:

Electronic components: serial numbers and QR codes are marked on the surfaces of integrated circuit chips, resistors, capacitors, etc., with a clarity of micrometers and long-term color retention.

Precision manufacturing: Achieving deep engraving and marking on high hardness materials such as molds and aerospace components, with a depth control accuracy of 0.01 millimeters.

4、 Wide material adaptability: covering both metal and non-metal materials

Fiber laser marking machine can process materials including:

Metals: stainless steel, aluminum alloy, copper, iron, etc., especially good at high melting point and brittle materials (such as ceramics, carbon fiber).

Non metals: plastic, glass, leather, wood, etc., different effects can be achieved by adjusting laser parameters (such as glass engraving, wood relief).

Special materials: Supports processes such as blackening anodized aluminum and white marking on transparent materials.

5、 Non contact processing: Non destructive product surface

The laser beam achieves marking through the action of light energy, without the need to contact the workpiece, avoiding the following problems of traditional mechanical processing:

No mechanical stress: prevents workpiece deformation or cracking, especially suitable for thin-walled and precision parts.

No tool wear: Reduce consumable costs and minimize downtime caused by tool replacement.

Small heat affected zone: The temperature rise in the processing area is low, preventing material thermal damage (such as plastic melting and metal oxidation).

6、 Intelligence and Automation: Integrated Production Process

The fiber laser marking machine is equipped with an advanced control system that supports:

File format compatibility: Directly read various design files such as PLT, DXF, BMP, JPG, etc. without the need to convert formats.

Automatic coding function: supports automatic generation of dynamic information such as serial number, batch number, date, etc., to meet traceability requirements.

Visual positioning system: By recognizing the position of the workpiece through a camera, high-precision alignment and marking can be achieved to adapt to the processing of irregular parts.

Multi axis linkage control: can be paired with a rotating worktable and a two-dimensional mobile platform to achieve 360 ° blind spot marking.

7、 Environmental Protection and Safety: Compliant with International Standards

No chemical pollution: The processing process does not require ink or solvents, avoiding the emission of volatile organic compounds (VOCs).

Low noise operation: The air cooling system has a noise level of less than 60 decibels, suitable for clean workshop environments.

Safety protection design: equipped with laser protective cover and emergency stop button, in compliance with international safety certifications such as CE and FCC.

8、 Compact and flexible: adaptable to diverse scenarios

Compact size: The overall weight of the machine is usually less than 20 kilograms, and it can be carried by hand to save space.

Easy installation: No need for complex water cooling system, ready to use upon power connection, suitable for rapid deployment.

Strong environmental adaptability: It can work stably within the temperature range of -20 ℃ to 60 ℃ and withstand harsh environments such as dust and humidity.

Expansion of application areas

The technical characteristics of fiber laser marking machines make them the preferred choice for multiple industries:

Electronic communication: mobile phone casings, circuit board markings, anti-counterfeiting and traceability.

Automobile manufacturing: engine components, airbag markings, high temperature and corrosion resistance.

Medical devices: surgical instruments, implant labeling, in compliance with biocompatibility requirements.

Packaging industry: Date coding and tamper proof design for food and drug packaging.

Jewelry: Carving on precious metal surfaces to enhance product added value.

Summary: Fiber laser marking machines have redefined industrial marking standards with core characteristics such as high efficiency, energy saving, long lifespan, high precision, and wide material adaptability. Its non-contact processing, intelligent control, and environmental protection characteristics not only improve production efficiency, but also promote the upgrading of the manufacturing industry towards green and precision direction.