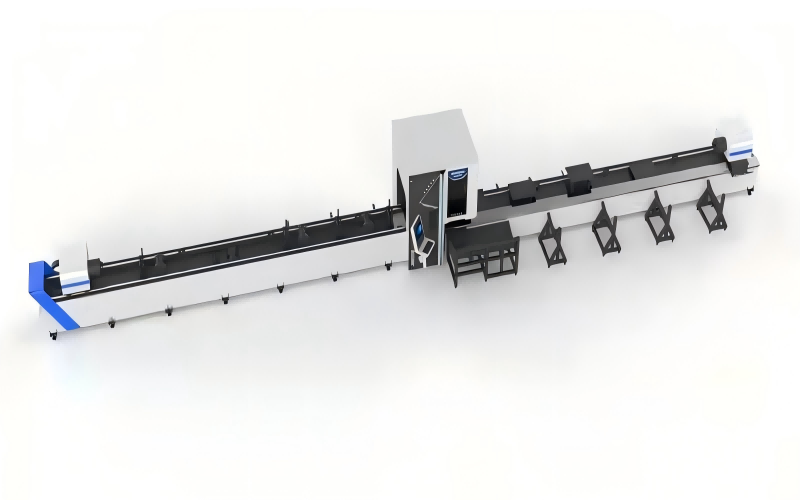

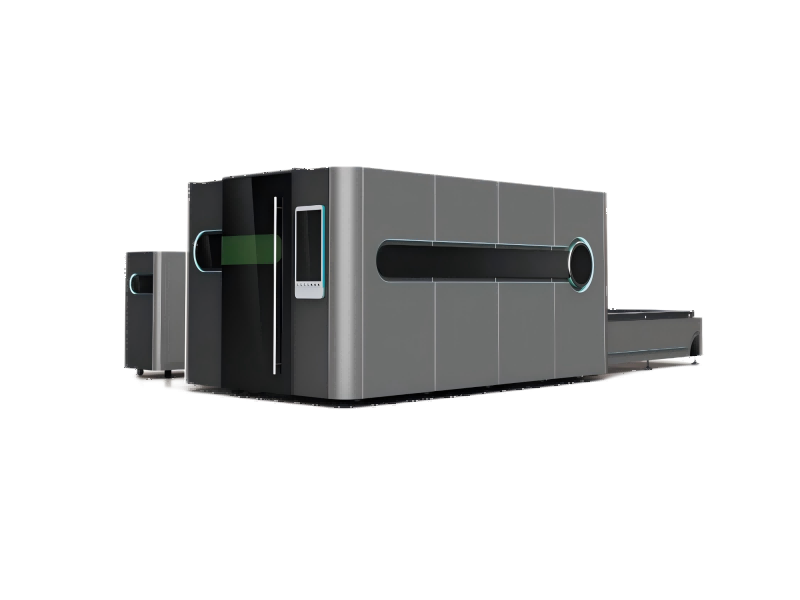

SHEET&TUBE FIBER LASER CUTTING MACHINE COMBINED H3015M

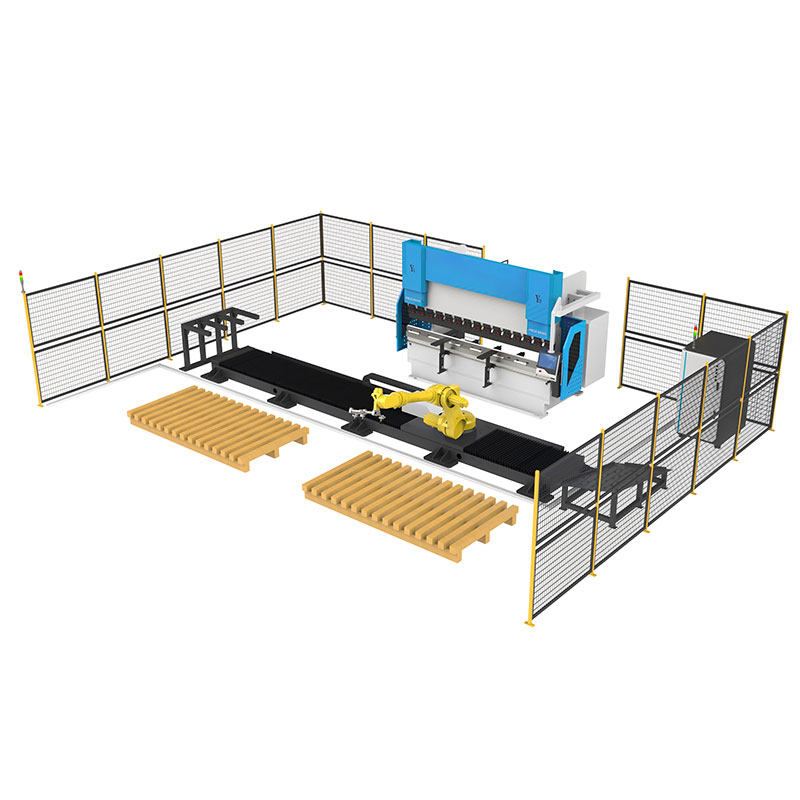

H3015M Fiber Laser Cutting Machine Combined Properties of H3015M: H3015M fiber laser cutting machine is widely used for cutting sheets and also offers an optional function for cutting tubes, which is why we refer to it as the M model. H3015M fiber laser cutting machine is designed for both tube and sheet cutting, offering dual…