I.Advantages of fiber laser weldding machine H1500W

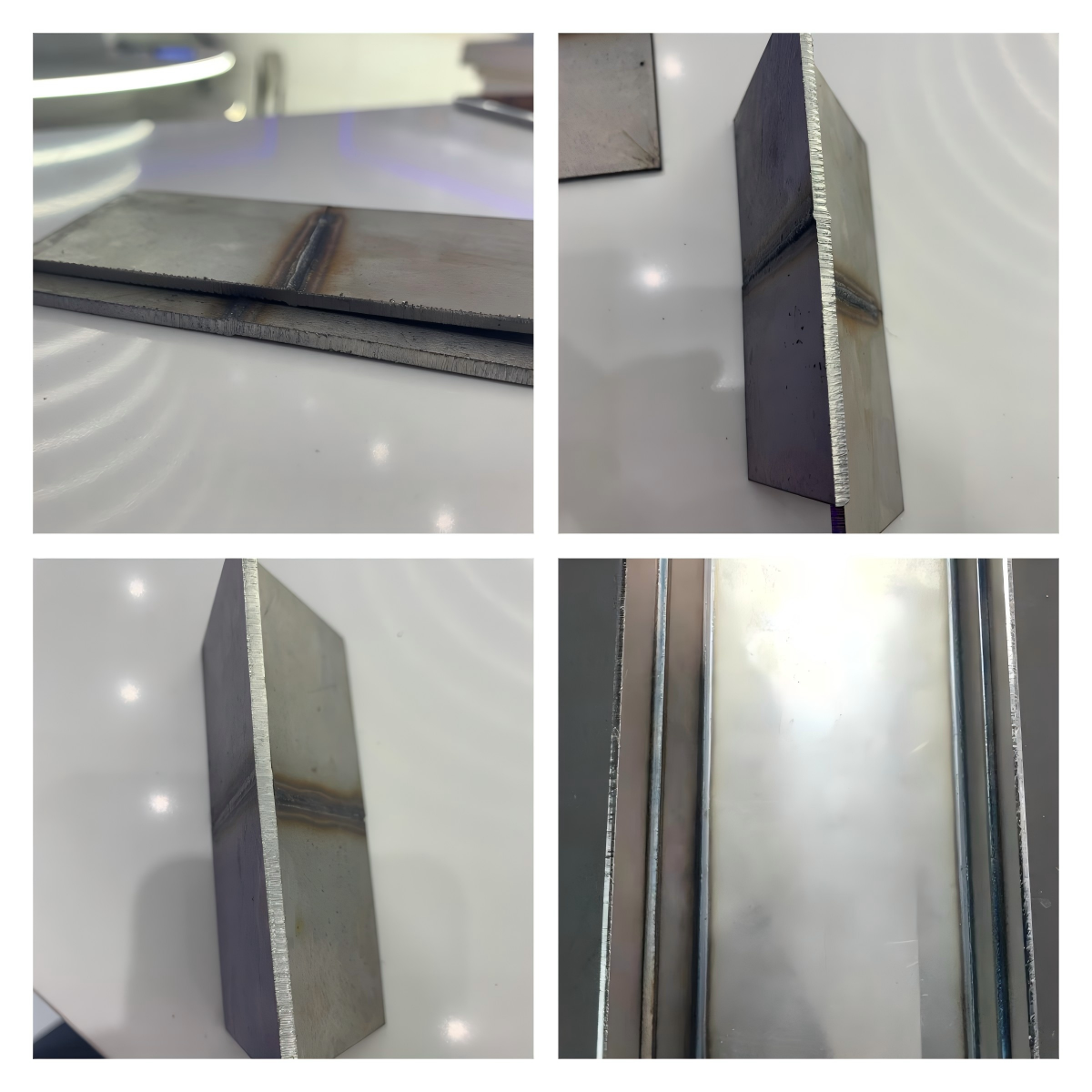

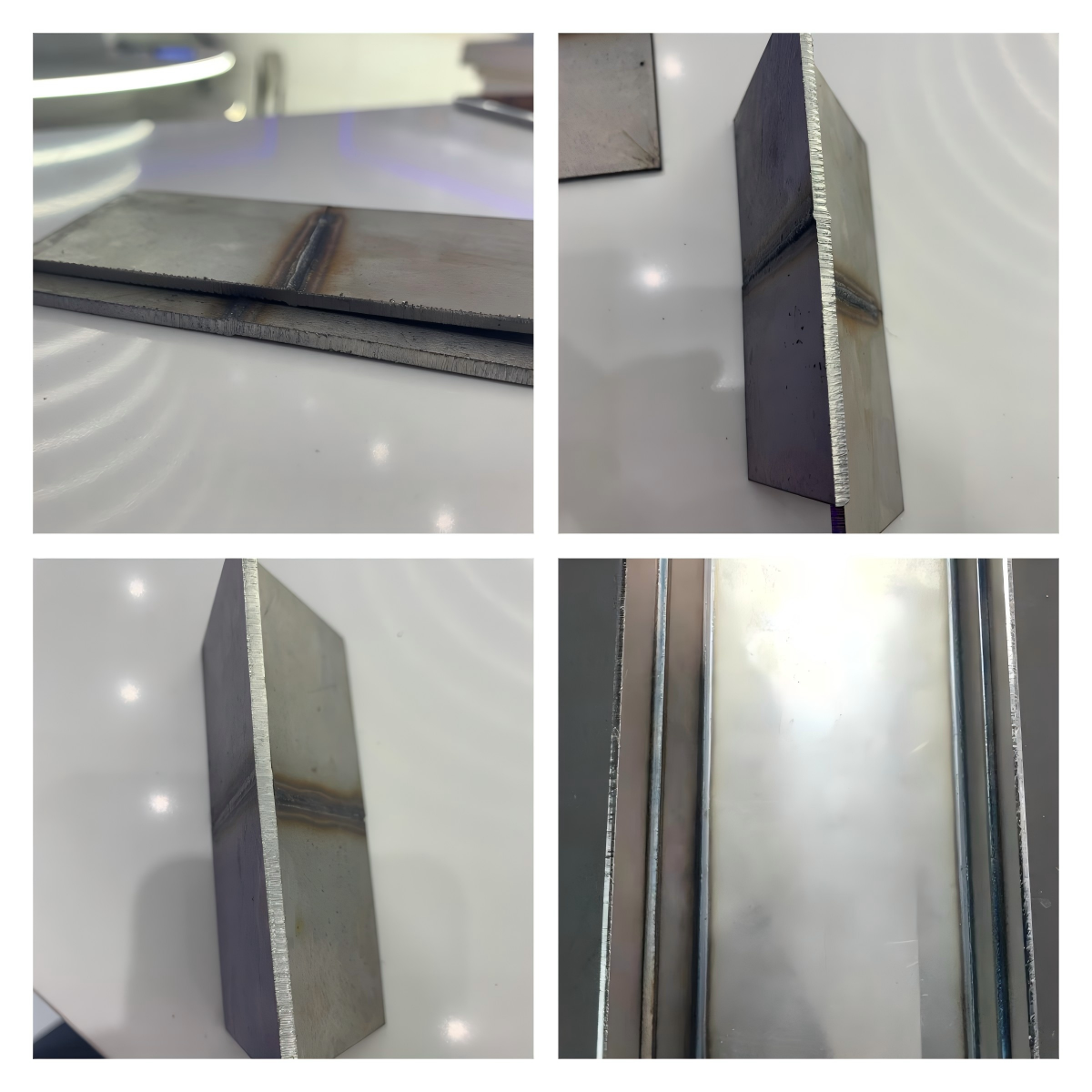

- Low technical requirements for personnel;

- The heat-affected zone is small and not easy to deform;

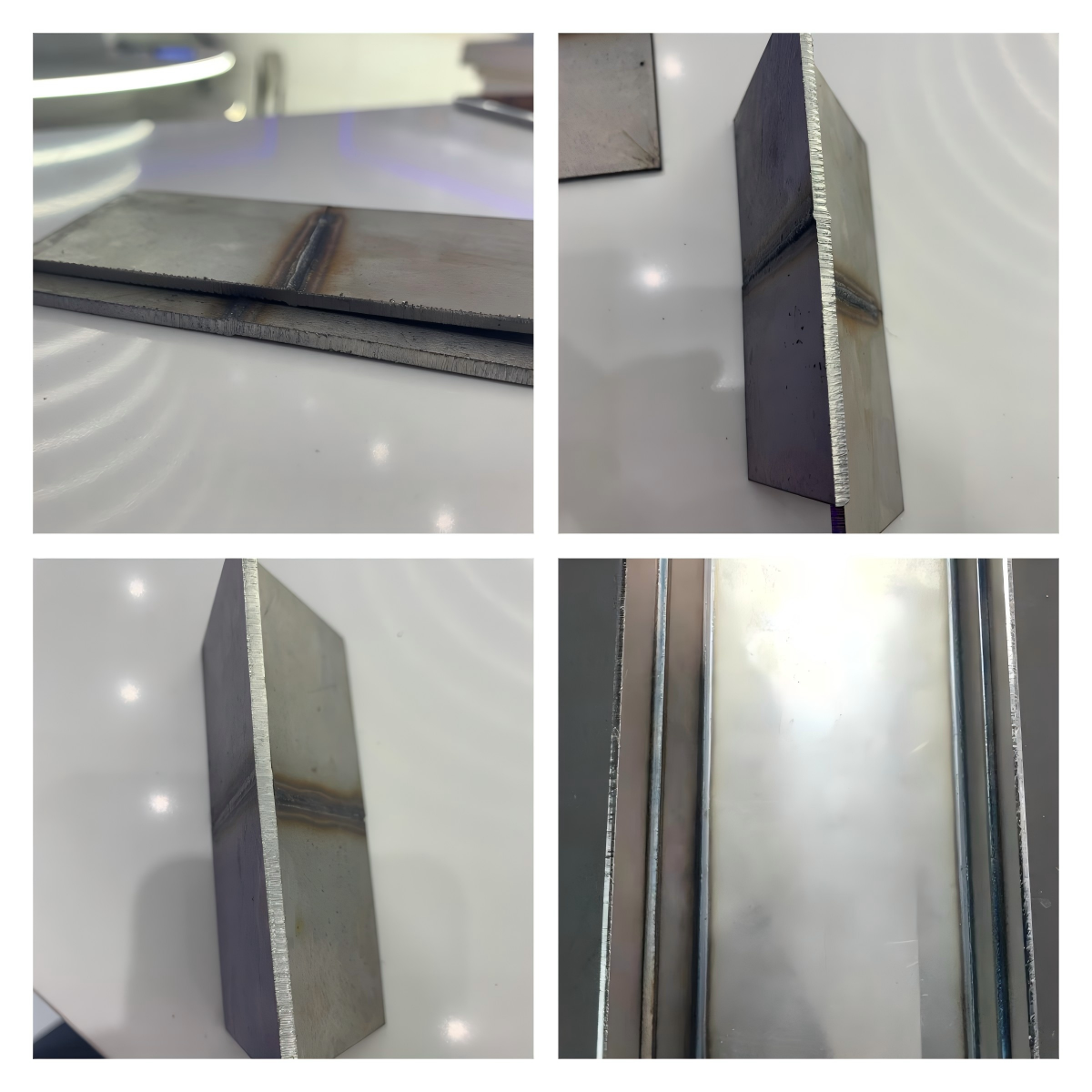

- The weld gap is narrow;

- Cool quickly;

- The welding quality is beautiful and no secondary grinding (or light grinding) is required;

II.Technical Parameters

| Laser Power |

1000w |

1500W |

2000W |

| Welding Material |

Stainless Steel |

Carbon Steel |

Aluminium |

Stainless Steel |

Carbon Steel |

Aluminium |

Stainless Steel |

Carbon Steel |

Aluminium |

| Welding Thickness(mm) |

2 |

2 |

1 |

3 |

3 |

2 |

4 |

4 |

3 |

| Welding Thickness(inch) |

|

|

|

|

|

|

|

|

|

| Adaptable welding wire |

welding wire diameter 0.8-1.6mm |

| Weld seam requirement |

filler wire welding≤1MM Swinging welding ≤15% of plates thickness≤0.3MM |

| Machine weight |

220KG |

220KG |

300KG |

| Machine size(mm) |

954X715X1080 |

954X715X1080 |

1155X715X1160 |

| Machine size(inch) |

|

|

|

| Welding gun line length |

10m(The wire feed tube of the wire feeder is 3 meters long) |

| Welding gun weight |

Vibrating mirror type(Qi Lin):0.9KG |

| Machine Power |

7KW |

9KW |

12KW |

| Language supported |

Standard: Chinese, English, Korean, Vietnamese, Russian

Japanese and Spanish can be customized ( delivery time plus 7 days) |

| Voltage and frequency |

Standard:380V/50HZ Other voltage and frequency is optional |

III.Welding Materials&Application

Laser welding machine can be used in welding stainless steel, carbon steel,aluminum,chromium, nickel, titanium and other metals;

Fiber laser welding machine is widely used in the IT industry, medical equipment, communications equipment, aerospace, machinery manufacturing, battery manufacturing, elevator manufacturing, craft gifts, household appliances manufacturing, tooling, gears, automobile shipbuilding, and other industries.

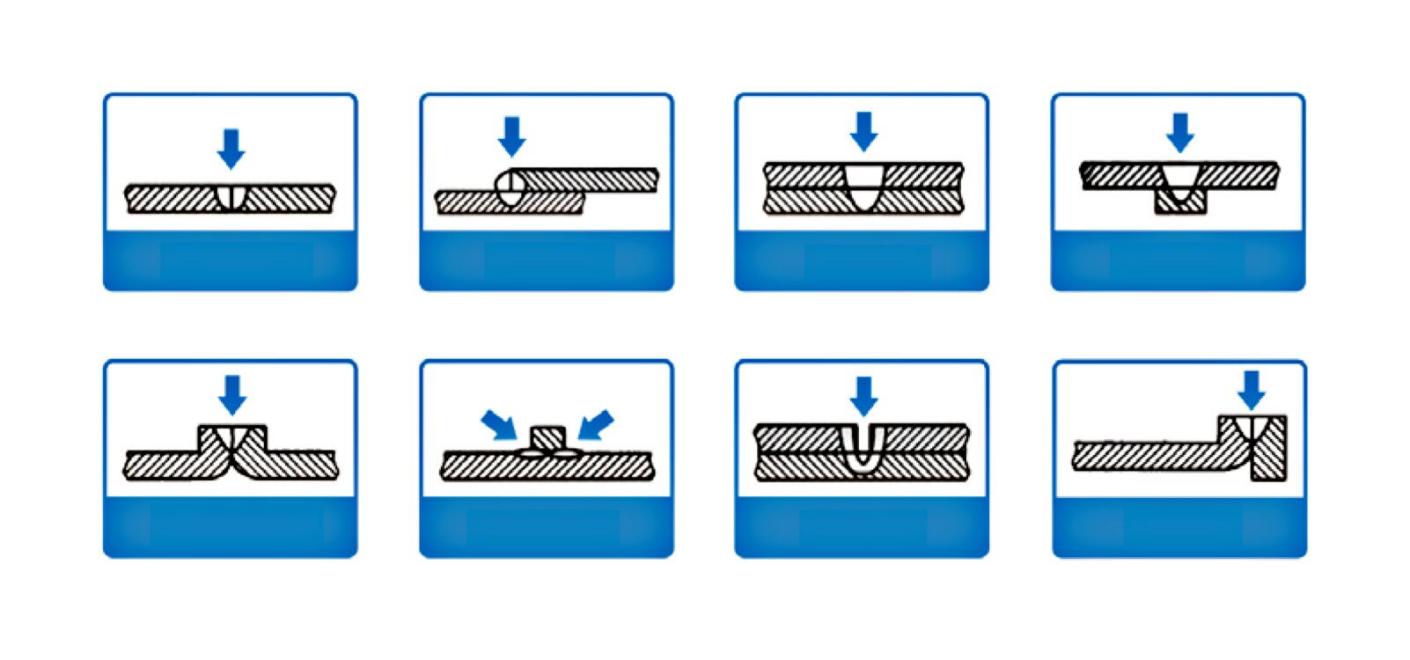

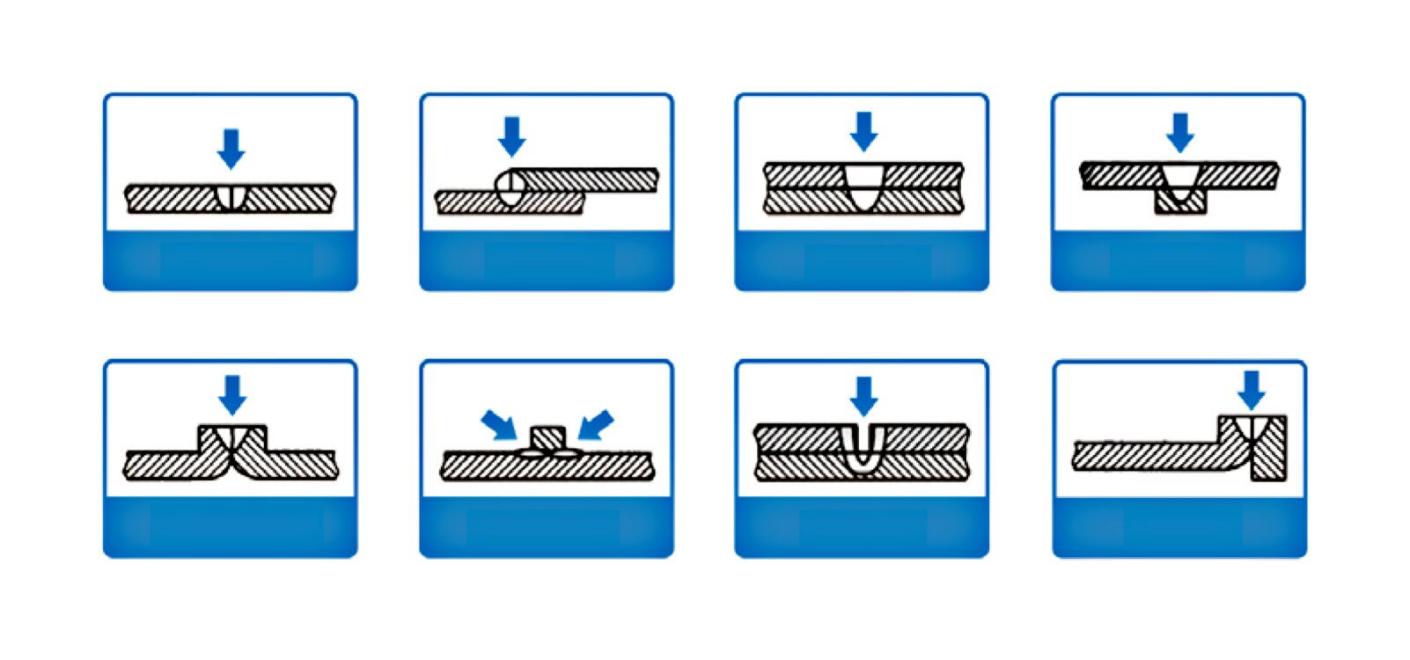

- Comparison of laser welding and traditional welding methods

| Comparison item |

Traditional welding |

Laser welding |

new generation laser welding |

| Heat input to the workpiece |

Very high |

Low |

Low |

| Deformation of the workpiece, undercut |

Huge |

Small |

Tiny |

| Bond strength to base material |

Average |

Good |

Great |

| Subsequent processing |

Need sanding |

No sanding or a bit sanding |

No sanding or a bit sanding |

| Welding speed |

Average |

More than 2 times of argon arc welding |

More than 2 times of argon arc welding |

| Applicable materials |

Stainless steel

carbon steel

galvanized sheet |

Stainless steel

carbon steel

galvanized sheet |

Stainless steel

carbon steel

galvanized sheet |

| Supplies |

Plenty |

A few |

A few |

| Operation difficulty |

Complex |

Average |

Easy |

| Operator’s safety |

Not safe |

Safe |

Safe |

| Environmental protection impact |

Not environmentally protective |

Environmentally protective |

Environmentally protective |

| Welding fault tolerance |

Bad |

Good |

Great |

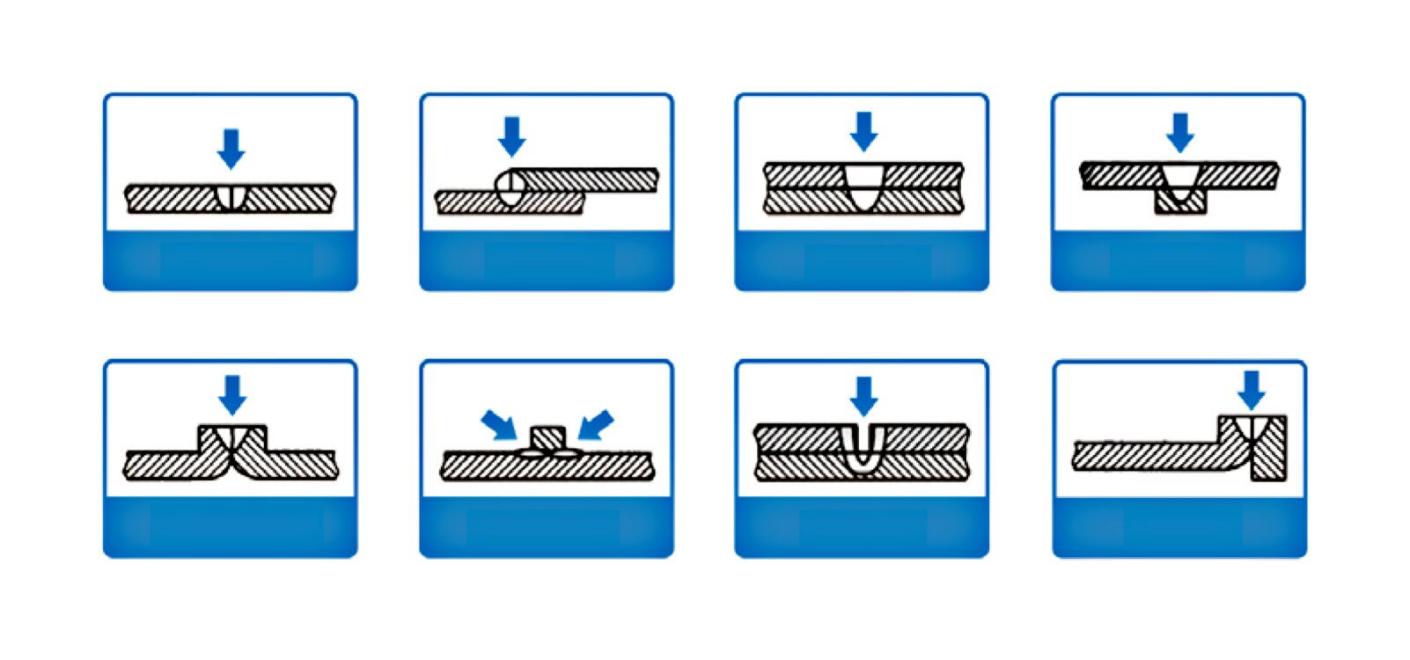

| Weaving welding |

None |

None |

Equipped |

| Adjustable light spot width |

None |

None |

Equipped |

| Welding quality comparison |

Low |

Average |

Super High |

1.Labor cost

- Labor cost of argon arc welding: argon arc welding requires a mature welder. The monthly salary of a mature welder starts at USD1200. The labor cost for a year is USD1200*12=USD14400;

- Hand-held welding labor cost: Hand-held welding is simple and easy to learn. Ordinary operators can learn it within 1-2 days. The monthly salary of ordinary operators is generally about USD600, and the labor cost for a year is USD600*12=USD7200; so In terms of labor costs alone, replacing argon arc welding with handheld welding can save USD7200 of wages per worker per year.

- Argon arc welding welders are “difficult to recruit” and require extremely high experience and skill level for welders. Laser welding can also be operated by non-professional personnel. “Getting started and welding” has become a unique advantage of laser welding. Moreover, as labor wages have increased year by year, this has further increased the labor costs of enterprises. The cost of a professional welding worker and a general worker has generally reached a gap of 2-3 times.

2.Deformation The heat of the laser welding machine is more concentrated, and the thermal deformation caused by the material is small. The heat-affected zone of laser welding is only one-tenth of that of argon arc welding. When the thin plate is fully welded, the deformation is also the smallest.

3.Welding quality Laser welding machines have more advantages in welding thin-walled materials. In terms of accuracy, the laser welding machine has higher precision, and the laser welding machine is more beautiful. The subsequent welding basically does not need to be polished, which reduces a process, and saves time and trouble and saves the cost of polishing.

4.Welding speed For a mature argon arc welding worker, we assume that he can weld 10 products in an hour. We conservatively estimate the speed of laser hand-held welding. At least 20 products can be welded in one hour; it is equivalent to the capacity of two argon arc welding workers. The annual salary of 2 argon arc welding workers is USD29500; one hand-held welder’s annual salary is USD7500; the saved salary is USD22000.

V.Configuration

| NAME |

NO. |

BRAND |

| Case/control cabinet |

1 |

HUARUI |

| Water chiller |

1 |

HANLI |

| Pneumatic part |

1 |

SCHNEIDER/AIRTAC |

| Welding system |

1 |

STANDARD |

| Laser source |

1 |

RAYCUS |

| Welding head |

1 |

Standard |

| Maintenance tools ( protective eyeglass ) |

1 |

HUARUI |

| Instruction manuals |

1 |

HUARUI |

| Certificate of machine |

1 |

HUARUI |

VI.Cost

| ITEM |

1KW |

1.5KW |

2KW |

| Nitrogen welding |

Nitrogen welding |

Nitrogen welding |

| Nitrogen welding |

RMB/H |

0.5/H |

| USD/H |

0.076 (1USD ≈ 6.54RMB) |

| Gas consumption (continuous welding) |

|

0.01m³/H |

0.01m³/H |

0.01m³/H |

| Total power |

|

7KW |

9KW |

12KW |

| Total electrical consumption

(Take 60% welding efficiency) |

|

4.2KW/H |

5.4KW/H |

7.2KW/H |

| Total running cost(continuous welding)

(as per 0.15$/kwh) |

RMB/H |

19/H |

20.98/H |

22/H |

| USD/H |

2.91 |

3.21 |

3.36 |

Note: The electricity prices and gas prices in the above list are for reference only, and prices may vary from region to region. Because workers cannot perform continuous welding for a long time in actual use, the actual use cost will be lower than the estimated data.